The Wanderer Story

or, How a couple of car guys took this:

and turned it into this:

It started as a very simple dream: find a old sturdy boat, clean ‘er up, bolt some nice motors on it, take it down to Costa Rica and go fishing.

I bought the Wanderer March of 2009, figuring I had what I needed in the form of my auto shops in Jacksonville and my good friend Captain Jack Weinnman (an experienced angler in his own right and an ASE Master Mechanic).

We also enlisted Matty from the car lot, who despite knowing absolutely nothing about boats seemed willing to perform the manual labor, keep the shop clean, and run out for parts/food.

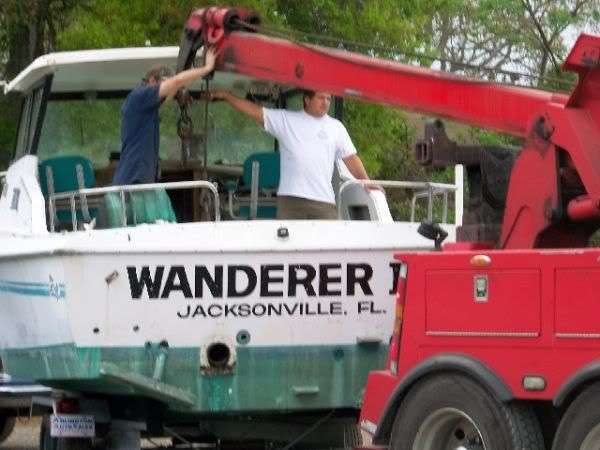

The Wanderer herself was for sale in nearby Mayport, FL by the widow of the late Captain Jack Woodruff, a local legend in the Northeast Florida fishing community.

The Wanderer was a 1983 T-Craft Cabin Model with inboard diesel power and had been rigged for light fishing and heavy relaxation: Full interior lighting, shower, heating, air conditioning, five-speaker surround sound…you get the idea.

With the team assembled and the boat at our shops in Florida, we began the first task of stripping the Wanderer of all major systems and components…basically all the way down to the stringers and the hull.

It was during this process that our respect for Captain Woodruff and his boat began to take shape. EVERY bolt, nut, washer, and screw was tight and properly serviced. He had poured so much time and energy into the Wanderer that I knew we were going revive this boat to perfection.

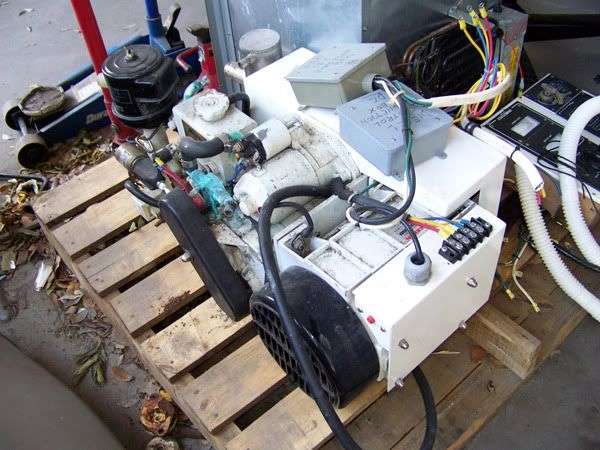

We quickly learned that things don’t come out of boats quite as easily as they look…if you don’t believe me try to pull a 300lbs. Markon AC Generator through an opening the size of a doggie door.

Calling on Captian Chris Savitz and his father for an assist, Jack and Matty gutted the boat over a three week period. The finished the tear-down by pulling the diesel inboard at the end of May.

At this point, the guys in the shop got back to cars and I took the Wanderer to South Florida. At Whitewater Boat Corp. in Miami, FL she received a fresh coat of blue bottom paint, new deck panels, and a sturdy transom for the forthcoming Yamahas. Then it was over to Blue Water Towers in Boyton Beach, FL for the canopy tower.

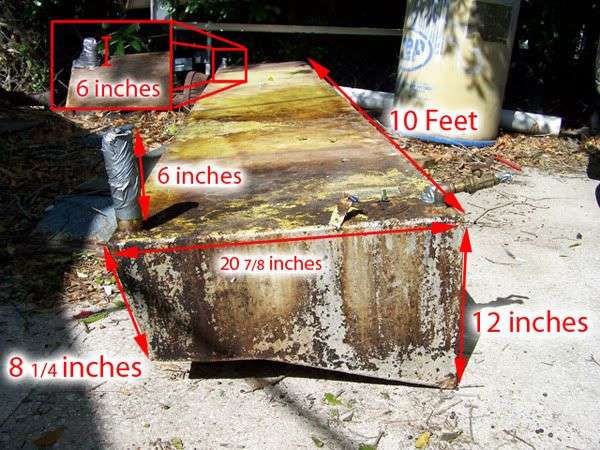

Around this time in the project it became apparent that we must think ahead to the kinds of problems boats have years after their built. The Wanderer is bound to live out her years in Costa Rica roughly 1200 miles from a decent boat shop. This was very apparent when we saw the condition of the fuel tanks.

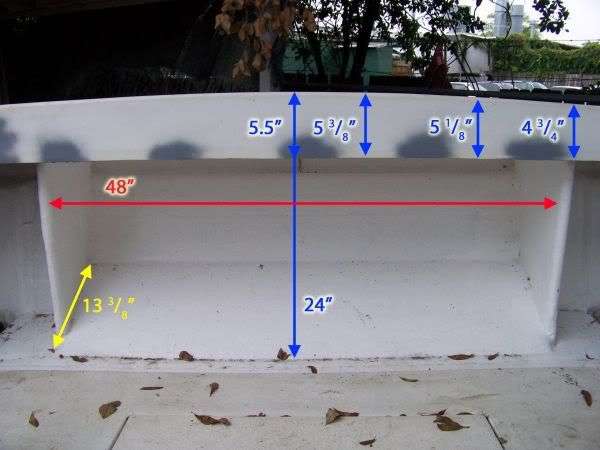

Clearly this tank was not ready for Costa Rica. Jack and Matty got the unenviable task of pulling both 200 gallon tanks and draining them of old diesel. Then using this measured graphic and some incredible phone skills Jack had a welder fabricate two perfect replacements. This is a small example of the attention to detail that is necessary throughout a project like this.

The Wanderer returned to home base in July, when we enlisted yet another car guy to make this boat happen. Martin Rodriguez is a freelance paint and body specialist who does a lot of car work for me. He is a Tico (by way of New York City) and he does really nice work. He’d never done a boat this size, but figured it was worth a shot.

Along with his assistant Dave, Martin did a fantastic job with this boat. The blue puts even the Costa Rican waters to shame.

We devised a slick way to install the live well using existing structures in the hull, and turned to Oasis Boatyards in St. Augustine, FL to do the fiberglass fabrication.

These guys did an outstanding job and even drove the 90 mile roundtrip to come help us with the final details. They could’ve made us bring the boat to them, but I feel showed a lot of class by going out of their way for us.

By the end of July we saw the Wanderer in her new colors, and we got our first glimpse of how awesome this thing could be. Jack and I built a black Lexan Console while Matty got deep into polishing and buffing the bow rails, anchor box and every nut, bolt, and washer we pulled off the boat.

It was also around this time that pictures of this boat were first included in the monthly Fishing Nosara Fishing Report, which in turn led to a flurry of calls, emails, and visits to the shop to see exactly what we were up to and exactly how crazy we were.

With tons of “advice” from these spectators we got down to installing the instruments, steering, fighting chair, tower, new rub rails and live tuna tunas, plus outfitting the interior to comfortably support twelve anglers. Jack busied himself with all the wiring while Matty and I prepped the bow rails, anchor assemblies, and teak trim.

We brought in Carl Schmidt (first mate on my boat Fishtastic and a master carpenter) to assist our refit of the cabin. Where once was a refrigerator, AC generator, and freshwater recycler is now a rack of custom tackle boxes.

September was a month of furious activity as the deadline for shipping loomed at the end of the month. We finished rigging the bottom machine, bilge pumps, tuna tubes, and a half-dozen or so other systems with about a week to spare.

The last hurtle was getting a custom piece of 1.25 inch thick steel to anchor the fighting chair directly to the stringers. My son Craig Jr. is a master fabricator and he came through with an extremely strong anchor plate that will keep that chair in the fight for decades.

The motors were waiting in Costa Rica, but everything else was ready to fish when we sent her off on September 22.

After eight months of sweat, stress, deliberation, frustration, aggravation, sleepless nights, seven-day work weeks, dozens of trips to boat/metal/woodworking/tool and die/machine shops, twelve tubes of 5200, six ruined drill bits, a few hundred pages of Customs paperwork, and a 1,500 mile boat ride…the Wanderer arrived safe and sound in Nosara in early October.

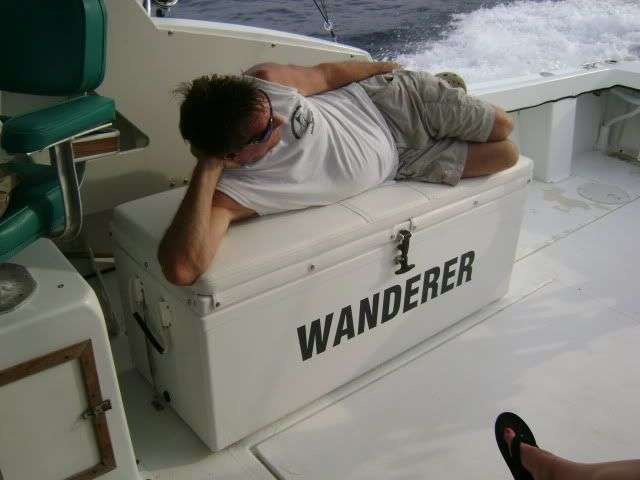

I arrived in November to oversee the installation of the motors and the final rigging of all the tackle. You can see that Alex (the Wanderer‘s First Mate, second picture down) was ready to man his station even before we had the motors on!

Using seven strong men and a stronger tree branch, we got the motors in place as our Yamaha representatives oversaw the final installation, priming and inital firing of the twin 150 motors.

For those who have never witnessed a boat launch on the beach with a backhoe, it’s certainly a thrill…especially when that’s your boat our there! These Ticos are pros, and they know what they are doing.

Eight month since purchasing the Wanderer she was back in the water on November 13, 2009.

We wanted to christen the Wanderer with some lady luck (or karmic Zen blessings, depending on whose side you believe) so we invited some of the local Yoga students to come along for the test drive.

Something worked right because the next day Mike Young, Larry Mayo, and Clyde Gardner caught this gorgeous Black Marlin…the first on the Wanderer and a Hall of Fame catch.

Then the Wanderer got into some serious fishing. On the 15th I pulled up a 45lbs. Dorado and a nice sailfish. Also our first client Jimmy Dougherty caught his first ever Yellowfin tuna.

November 16th I brought in five 40lbs. Dorado and a 200lbs. Black Marlin along with my good buddy Chris Savitz (who remember helped get the inboard motor out of the Wanderer back in the Spring).

On November 17th we lost a HUGE 700lbs. Marlin right at the boat, but we cheered up by boating ten 30lbs.- 40lbs. dorado and ten 30lbs. Yellowfin tuna. We nailed ’em again on the 18th; along with Javier Hernandez we caught a 300lbs. Black Marlin, six 20lbs. yellowfin and a pair of 30lbs. dorado.

Finally on the 21st Matty was aboard the boat he poured so much sweat, blood, and energy into. I am happy to report that his first catch on the Wanderer was this beautiful 30lbs. dorado.

I’m loving life right now. You’re welcome to come on down and join us. Trips on the Wanderer are being booked left and right, so hurry up and reserve your dates today. Thanks again to everyone who was part of this project. It’s been a heckofa trip.

Craig Sutton

November 27, 2009

![]()

The beginning of the rainy season in Costa Rica is September 1st. While most resorts furlough their employees, at Nosara Paradise Rentals and FishingNosara we keep our full staff together for two months of intensive maintenance and expansion of our boats, vehicles, safari carts, and properties.

In this special edition of the Costa Rica Fishing Report, we will take a behind-the-scenes look at the projects and people that will make 2012 our best year to date.

The Wanderer will be entering her third year of service (man, time flies! It seems like yesterday we sent the Wanderer to Nosara) and she was ready for a major refit. An every-day boat like this demands lots of annual upkeep, and this season put a few new scars in the blue beauty that would take Craig Sutton Jr.’s expertise to repair.

In late August, the Wanderer was damaged when she was engulfed by a rouge wave at her mooring point in Garza Bay. As the 31-foot craft bucked in the waves, the entire weight of the boat clung to the rope through the steel pulpit on the nose.

Here is what Craig was looking at upon his arrival on September 1:

The first step was to prepare the work area with a makeshift tent to keep the exposed fiberglass dry; this ensures that the new fiberglass resin will set up and harden without trapping any air bubbles or wood-rotting moisture.

Once Captain William and First Mate Alex completed the rain guard, Craig and Matty got down to the dirty work of sanding/grinding the damaged material.

Now it’s time for some fiberglass. Because of the huge industries of boating and surfing, the quality of fiberglass resin and hardener in Costa Rica is actually better than what we get in the USA; it has less impurities, sets up faster and sands cleaner.

Notice how Craig puts a wad of material as deep in the hole as possible; this works in conjunction with the layers inside the anchor box to create a pure fiberglass plug that is form-fit to the hole.

After the first day of fiberglass, the nose of the Wanderer was watertight once again.

However a few more coats of resin and a lot of fine sanding would still be required to bring this area back to pre-damage conditions.

Notice how the deck line is still not quite straight (see right); we let the repair cure and dry before coming back a few days later to sand, add more fiberglass, and put the finishing layer on.

Craig and Matty were back at it on September 7 for the final touches. By using a flat edge of cardboard rather than a paintbrush, Craig was able to create a near-perfect flat surface for the final layer.

One more late night of sanding, and Craig stepped away from this repair confident that the nose of the Wanderer is stronger than before and the surface under the pulpit is as smooth and level as a dance floor.

Of course it is easier to have a professional do your fiberglass work (or any boat work for that matter), but the quality and attention to detail that comes from working on your own boat can not be understated.

Take for example the passageway to the forward observation deck. The Wanderer‘s clients have grown to love this panoramic view of the Pacific for photography and the easy access to sunbathing on the prow.

These photos (right, below) were taken in November 2009 when this boat was fresh as a daisy.

Unfortunately this porthole has taken a beating over the last two years and the bolt hinge got completely stripped.

While waiting on fiberglass to dry, Craig tracked down a tap-and-die set and cut a fresh hole for the hinge bolt. This repair, while small in scale and expense, is an example of the attention to detail required to keep a 31-foot boat running in Costa Rica.

The final step to get the Wanderer ready for many more years of bad to the bone billfishing was to tighten the canopy top and freshen the 5200 Marine silicon that keeps the sea spray out of the cabin.

After lifting the roof and supporting it was some trees we found laying around (“Costa Rican jackstands” Matty called them), we applied fresh 5200 and 3.5 inch new stainless screws to replace the 20+ year old, 2.5 inch fasteners.

The increase in strength all-around is obvious, ensuring many more years of service from the rugged Wanderer. Craig and Matty left Nosara on September 10, then Captain William and Alex finished the paint work on the nose,

First Mate Alex is also a first class carpenter as evidenced by this beautiful new rigging table in the cabin of the Wanderer. This replaces a worn piece of paneling that did nothing to add to the look or function of the cabin. Now we have this great multi-use space for years to come.

From the nose to the propellers and the bottom paint to the roof, the big blue beauty will be all fixed up and ready for action come November 1.

![]()

Finally, many readers sent comments on Captain David’s beautiful rod rack he built for our vintage Safari cart last month.

First Mate Alex (who is an amazing carpenter in his own right) wasn’t about to let his good friend get the best of him, so he set out on his own woodworking mission.

The result is this beautiful rod holder to mount to the Wanderer‘s fighting chair.

Two things to notice here:

1.) I was just at the St. Pete and Ft. Lauderdale Boat shows and I did not see this level of woodworking craftsmanship, even with all the big-money boat builders in attendance.

Between the wood grain and the stain this piece has a finish that looks a mile deep.

2.) Ya gotta love a guy who does this on his day off! For a man who puts in 12-hour workdays on the water to sacrifice his own time shows Alex’s dedication to his boat and the FishingNosara team.

Off Season Maintenance 2012

It’s the rainy season in Nosara and we all know what that means….boat maintenance time! The captains and crew have the grounds of Nosara Paradise Rentals all to themselves and are dead-set on reloading the fleet for another record setting season. Let’s take a lot around the grounds:

The Explorer looks good as usual, and it’s required repairs are relatively minor and cosmetic.

The Adventurer is so new that it only requires some screw tightening. That only leaves…

The mighty Wanderer! After 3 years and nearly 600 trips our flagship is quite ready for a complete repaint and refit. This craft has taken everything that the Costa Rican environment could throw at her and is still hanging tough, but if you want a boat the last for 30 years you can’t skimp on the upkeep.

Our typical offseason painting on the boats consists of spot fixes and lots of masking tape. It is our goal to bring this paint job back up to the original level that we shipped to Nosara, so we are disassembling as much as possible. No tape lines on this boat!

Back in 2009 we were satisfied with the condition of the cabin, but now it is time for the chambers to get some TLC. The wood is still good in the cabin, but the paint is beginning to fade. Also we are deleting the hardwood shelves that ran along the sides of the cabin in order to save weight and reduce clutter.

The fuel tanks were another issue of concern. Three years ago we installed the tanks in what we thought was a watertight compartment. We were so confident that we did not paint the tanks so they are vulnerable to even the smallest drop of moisture that could sneak through.

Looks like we dodged a bullet there! This tank is almost exactly as we shipped her and we will not make the same mistake twice. A protective paint job and fresh foam will help us sleep a little easier at night.

Craig, Craig Jr., and Matty showed up on September 5 (one day after the big earthquake) and brought the requisite sanders, sandpaper and paint supplies. Removing the bottom paint is the hardest job we have ever asked of the boat crews, and despite the pain and itchiness they have made excellent progress stripping off 20+ years of old paint.

Despite the backbreaking discomfort of paint grinding, the crew jammed it out and kept their usual high spirits through the difficult times. One small step for man, huh David and Alex?

The prep work continues inside where the boys have dutifully taped off the cabin wood and started double-action sanding the floor, walls and ceilings.

First Mate Alex is an ace carpenter, so he is in charge of sanding and refinishing all of the cabin interior wood, the cabinetry, and the dis-assembly and cleaning of the fighting chair. Take a look at the shine on this wood:

Once everything is stained and put back together this should be a beautiful piece of functional fish-fighting art.

After a few days of sanding the bottom paint off, we realized that the boat’s trailer was obstructing our ability to reach all of the area. Furthermore the impeded access would create too many null spots where we would have to come back and paint later.

The solution is pure Tico engineering…using two bottle jacks and big sturdy tree limbs as lifts, these fellas propped up this 3000+ lbs boat and slid the trailer out from underneath.

Sure enough this change enabled Craig jr. and the crew to finish sanding the bottom of the Wanderer. In hindsight this is the first step we would have taken, and in the future we will do all boat work down here in a saddle similar to this one.

We also employed a little local knowledge in dealing with another persistent adversary: the rain! During the rainy season in Costa Rica you can count on at least one gutter washer per day, usually in the late afternoon.

Our crew rigged up a tarp roof out of four smaller tarps and it is suited to repel most of the direct rainfall. Still with the humidity hovering around 99% we have to deal with condensation forming on surfaces we are trying to prep.

Matty and Carlos spent the better part of two days getting all of this paper and tape to adhere to the hull. Most of the effort was in pre-wiping the surface with acetone and quickly applying the tape before the water could re-establish it’s hold.

Also we ran a little short of paper so we resorted to the local tabloids…not only does this boat now repel paint but is also helps keep us up to date on soccer scores and silver screen starlets.

There was prep work still underway in the cabin and cockpit when Craig Jr laid down the first coat of gelcoat on the bottom. In their fervor to scrap the old bottom paint off, the crew accidentally went too deep in spots and exposed the top layer of fiberglass.

Here is the final prepped surface before painting; notice that the rough spots have all be filled with fiberglass resin and sanded down flush. Hopefully these patches will blend seamlessly once sprayed.

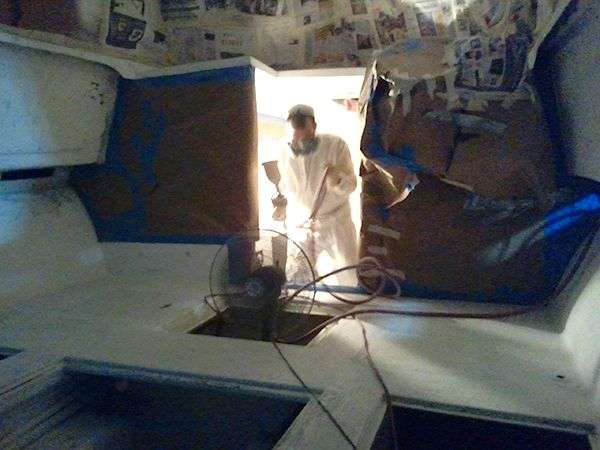

We thinned the gelcoat by almost 50% in order to spray it (most painters apply gelcoat via brush) and Craig drew the unenviable task of applying this nasty stuff. The mix of acetone thinner and resin catalyzer was a potent brew that required full facemask respirators to work around.

Due to rain it took a whole day to apply the bottom coat and another long night of spraying to finish the transom and all of the deck pieces.

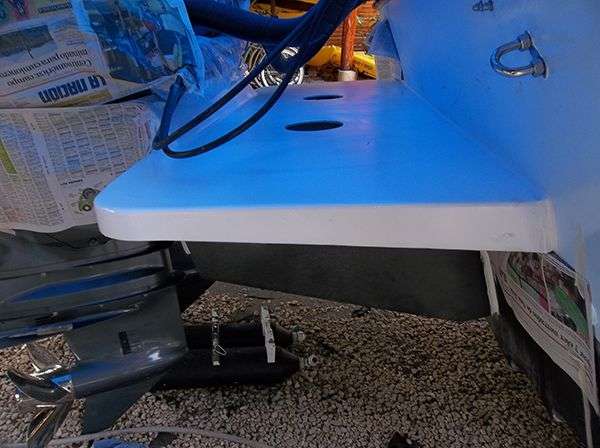

We were blown away by the great results from this chemistry experiment. Check out the smooth coverage of our two gallons of sprayed gelcoat:

It was around this time that disaster struck: our Dupont Imron paint had been seized by the Costa Rican port authorities. Apparently our shipping agent forgot to declare the paint products and our precious supplies disappeared into the underworld.

We first learned of this issue on September 6 and after two weeks of fruitless phone calls, the boat was nearly prepped and the whole project would come to a screeching halt without paint.

The boat crews stayed on task like true soldiers and finished up the surrounding work while the gringos set about figuring out how to paint this boat.

FishingNosara is famous for taking a bad situation and turning it into a legendary result, and the repaint of the Wanderer had become a bad situation. Finally the solution hit Craig Sutton like a bolt of lightning to the forehead: “Let’s gelcoat the whole dadgum thing.”

After all, every Tico panga boat you see gets an annual coat of gelcoat slathered on via brush and you can buy the stuff at any hardware store. The DuPont paint is world-class, and as such it is hard to find in such a remote location.

If we could combine the Tico’s time-proven approach of gelcoating with the gringo spray technique and attention to detail, then we might have a real one-of-kind result that will look great and last a long time.

Craig called on the experts: he asked Charlie Keen of the Discoverer Project and our good buddy Chappy if gelcoat would adhere well to fiberglass. Their replies were identical: “Well that is what it’s made for, Craig.”

Convinced, we dispatched Cumi to the Sur paint store in Nicoya and he retuned with 8 gallons of white gelcoat, 2 gallons of black bottom paint, 16 cans of acetone thinner, 10 more rolls of masking tape, and a few ounces of blue pigment.

On September 16, Craig Jr. and Matty set about turning this nightmare into a dreamboat. They hustled through the last few repairs on the boat, most significantly patching the old rubrail bolts and touching up last September’s front pulpit repair.

By 5pm all the fiberglass had cured and Carlos finished the final acetone wipedown. Normally the rains blow through at this time of night but it was an eerily clear evening; also Matty and Craig Sr. were scheduled to fly back to Florida to next morning.

The die was cast: all-night paint session!

Craig Jr. started with the hardest part which was the front cabin. This entire area was masked off tighter than the lid on a Pringles can, and literally every second of spray exposed Craig’s skin to low-grade chemical burns. Oxygen was scarce and only a small household fan was available to provide circulation.

This is what hell on Earth looks like:

After that horrible experience, the remainder of the interior was a breeze.

The floor was a little tricky, but the momentum was building and there was no stopping us now. Craig Sr. came through with dinner around midnight and the boys continued hammering away with only a few Flor de Cana breaks.

By 4am Craig Jr. was working down the sides…the home stretch!

They finished the job at 5:30am just in time for Matty to load up and head off to the airport. With his last gasp of energy, Craig Jr. issued the following orders to the crew: Don’t touch the paint, and take the sanding operation to the other side of the property.

After 12 well-deserved hours of sleep (and cure time for the white top), Craig Jr. kept the ball rolling by spraying the bottom paint:

Then came back on Saturday to apply the final coat of blue-tinted gelcoat.

After two weeks of worrying and stressing (not to mention almost working the crew to death), the Wanderer shines like a new dime.

Captain William is pumped with the finish, and Craig Jr. looks relieved to be on the way back home. The boys will finish up with the cleaning and will begin pre-assembling the components over the next four weeks.

Craig Sr. and Captain Jack will be back in late-October for the final tightening and water testing. After this process the FishingNosara flagship will be lighter, cleaner and shinier than ever.

Craig and Captain Jack have completed their first day of finalizing the Wanderer repairs. Here are the highlights:

First up was to fix the constellation of screw holes in the transom where the trim tabs have broken off multiple times (Thanks snorkelers!) and water had begun to intrude. Here’s what we were looking at back in September:

The water dripping down the rail tells the tale. We overdrilled these rotted holes until we found good wood and then left these holes under heat lamps for the last month. Confident in their dryness, the boys filled all the holes with fresh fiberglass.

We removed the trim tab piston (see the three hole pattern at the top of the photo) and snatched the pump out too…Captain William doesn’t even use trim tabs! He is able to trim the Wanderer with the motor tilt alone, so this will clean up the transom a bit.

We had a small intrusion spot on the port gunnel, so Jack and Craig cut out and replace a large precautionary section. Jack has gotten a crash course in this kind of work recently on The Discoverer Project.

A fresh layer of glass and it should be ready to go.

Lastly we have installed some of First Mate Alex’s master carpentry into the Wanderer. Here’s the bathroom door:

The fighting chair is an amazing redesign. Behold:

Here’s the big surprise. Polynesian Teak covering boards for the cockpit:

Once the glue dries and we get the batteries off, this is gonna be a beauty.

![]()

Thanks everyone for the great response to the Wanderer refit thread. Here are some fresh photos of the flagship as we get ready for our fishing season to kick off next week.

We addressed the Morse code-esque holes along the rear lip of the hull where a few generations of trim tabs used to be:

Next up was installing the rub rail and the thru-hull fittings on the outer hull. Lots of 5200 now means less troubles later!

The boys also tightened up the transom deck and painted over the fiberglass repairs from the trim tabs. The end result is a new-looking transom that should provide years of good service.

While Captain William and First Mate Alex tidy up the flagship and get her rigged with fresh line and new tackle, Captain David and Captain Carlos painted the bottoms of the Explorer and Adventurer to match the bad black on the Wanderer. This look helps tie the fleet together and should last much longer than the chip-prone blue paint we’ve used in the past.

It’s been a whirlwind eight weeks but I am proud to report that all three FishingNosara boats are ready to rock and roll! Keep a sharp eye the FishingNosara blog for catch reports, photos, and videos from the Best Sportfishing team in Costa Rica!

November 1, 2012 – Launch Day

Time to see if all the hard work pays off! The entire FishingNosara team was on hand to re-launch the refitted and repainted Wanderer.

As usual we waited for the high tide to peak at the western end of Garza, then David backed the mighty Wanderer into position on the shoreline.

Here is her last view of the shore without the water in the way for the next 9 months.

All hands were required to push her in, so we don’t have photos of that endevor, but you can always check out the Explorer Beach Launch Video to get the idea.

Our flagship vessel should now be ready for another 600+ great trips and she looks better than ever.

The refinished wood cabin, fighting chair, and teak covering boards are the eye-catchers, but those who have followed the Wanderer refit know how many essential non-cosmetic repairs went into the refit.

It was a grisly couple of months, but the sight of the blue beauty in the water and ready to fish makes it all worth the effort.

It’s October 2016, and the boats are on the hill and the houses sit empty, but the action never stops at Nosara Paradise Rentals and FishingNosara. Like all great franchises, we don’t rebuild…we reload!

It’s the rainy season in Nosara during the months of September and October, so this is the time of year when our team prepares for another great season.

At this point our fleet has outgrown our facilities, so this off season we’ll be breaking-in our new 30′ x 40′ boat garage.

After years of dodging rainstorms, laying fiberglass under tarps, and scattering our tools all over the yard it is great feeling to have a dedicated facility to perform our maintenance.

The garage also features a new bodega just for boat supplies; this way we aren’t mixing up boat stuff with Safari Cart supplies:

Great work by Deiter, Javier, and the rest of the staff in building this marine mecca!

Our flagship Wanderer is getting a major facelift this season…after 30+ years on the water the hard top is finally going away.

The wooden top has become waterlogged over the years, and the heavy glass windows are starting to show their age; in place of these fuel-hogging wastes of weight we will install a new aluminum top built by our friends at Custom Marine Jacksonville

Troy and the boys knocked us out with the quality of the top for the mega panga Harvester, so it was a no-brainer to let them loose on the Wanderer‘s new top…clearly Captain William is already thinking about how it will look:

Custom Marine has produced another masterpiece. Measuring 9 feet wide and 10 feet long yet weighing under 100lbs., this top is a marvel of marine engineering.

We had to build a custom crate in order to ship this thing…after all UPS doesn’t make a box this size!

The top is set for delivery this week and we will have it installed in plenty of time to start the new season.

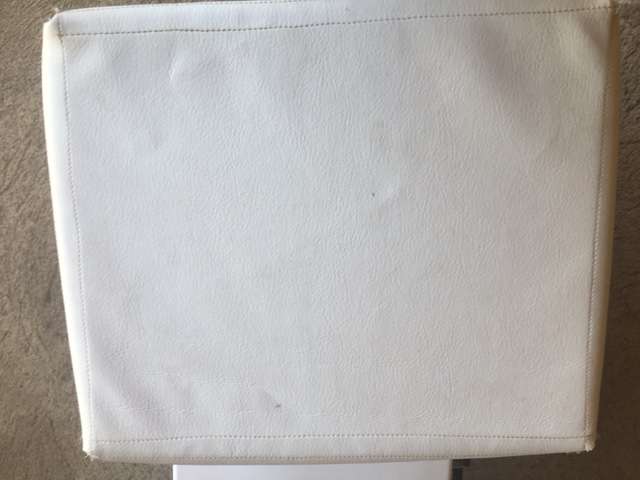

Also, all of the cushions on the boats are getting rebuilt and restitched by jack-of-all-trades Marino who is quickly adding sewing to his deep bag of tricks:

We are fresh home from Nosara and are proud to report excellent progress on the refurbishing of the Wanderer. To recap, this is what the boat looked like this time last year:

As our boat-building prowess grew, we came to realize the awesome power of synthetic Coosa Wood: super light and super strong. Last October we pulled apart the entire cabin and rebuilt all the pieces out of Coosa:

This change saves an estimated 400lbs. or more. It took the whole crew jamming for a week, but the new cabin made the boat ride like a champ and drink a lot less fuel.

This year we are continuing to shave weight by replacing the heavy wood top with a sweet tower built by our friends Troy and Harper over at Custom Marine Jacksonville

First step was to strip off the old top and prep the interior for sanding/fiberglass work.

There was a noticeable about of flex in the sides of the cockpit once the hardtop was gone; the windows, window frames, and top acted as a stabilizing connection. Therefore we had to replace the strength with these Coosa Wood ribs on the sides:

Fortunately the shipping crate for the tower has left us with a bounty of 12′ 2×4 lumber, so it was easy to brace these while the epoxy cured and layers of fiberglass were applied.

We test-fit the new top so we could mark our holes and epoxy-sleeve them:

It was obvious that the rear edge of the tower was a few inches too low, so we installed 2 inches of Starboard to lift the rear up to a 6’2″ clearance:

Our clients anglers tend to be big guys so we don’t want anyone knocking their head, however our Captains and Mates are short so the rod holders have to be reachable. This height seems like the perfect compromise.

Meanwhile, Brian installed our new command console to complete last summer’s wood-to-Coosa transformation. Here is the old console:

And here is the new console:

You can see that the switches and gauges has to be laid our differently per Captain William’s specs; after 1,000+ trips in 6 years the Master Captain has a firm grip on how he wants the tools laid out on the Wanderer.

This week the crew in Costa Rica will gelcoat the Wanderer inside and out, then reassemble her for the water.

We are aiming to be ready to fish in the first week of November, so keep an eye on the FishingNosara blog and we’ll let you know once she is back in her rightful place in Garza Bay.

After a whirlwind two month overhaul, the Wanderer is back in the water and ready to once again sit on the throne as the King of Garza Bay.

While it was a fun challenge to re-arm this flagship for another year of battle, clearly everyone is ready to get back to fishing…escpecially Master Captain William: