April 11, 2012 – Day 1

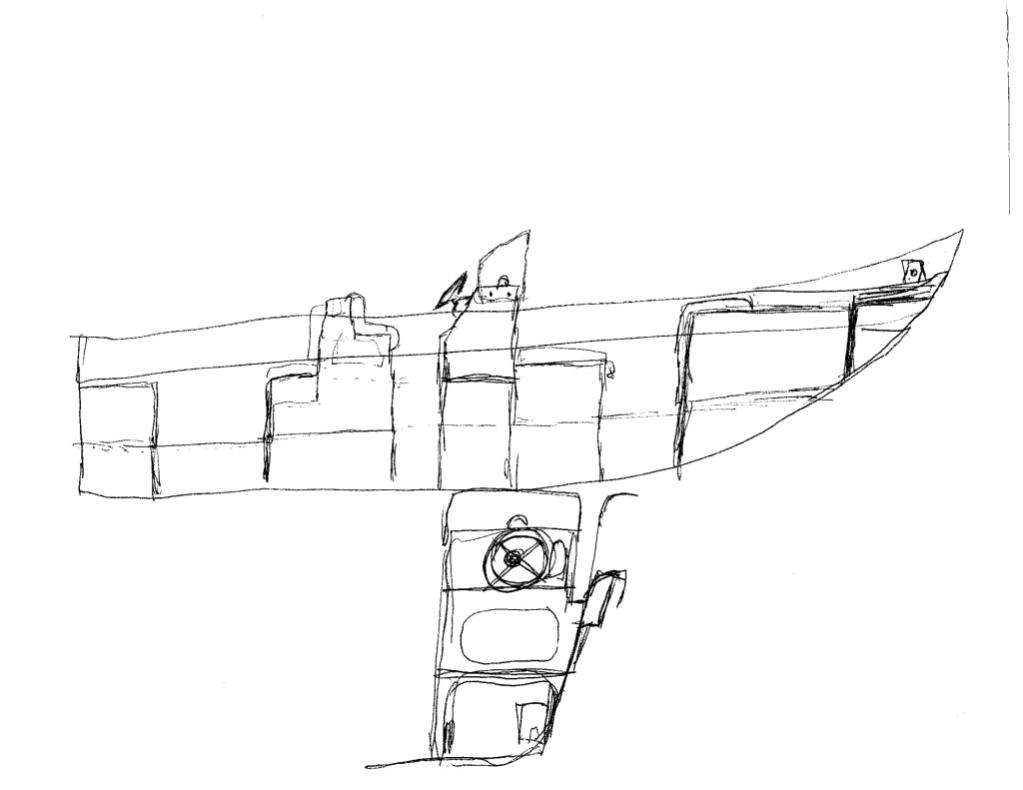

Welcome the newest member of the FishingNosara fleet, the 31-foot Discoverer!

With the success of the Wanderer, the FishingNosara US build team has selected another T-Craft to serve as our next great Costa Rican sportfishing platform. The 2012 season has been a record-breaker at FishingNosara and the demand for an additional large boat is evident.

The team gained experience with T-Craft on the Wanderer so going with the same hull is a natural choice. T-Crafts were originally built just down the road from us in Titusville, FL and though they shut down a few years back the evidence of their strength can still be seen at many marinas around the world.

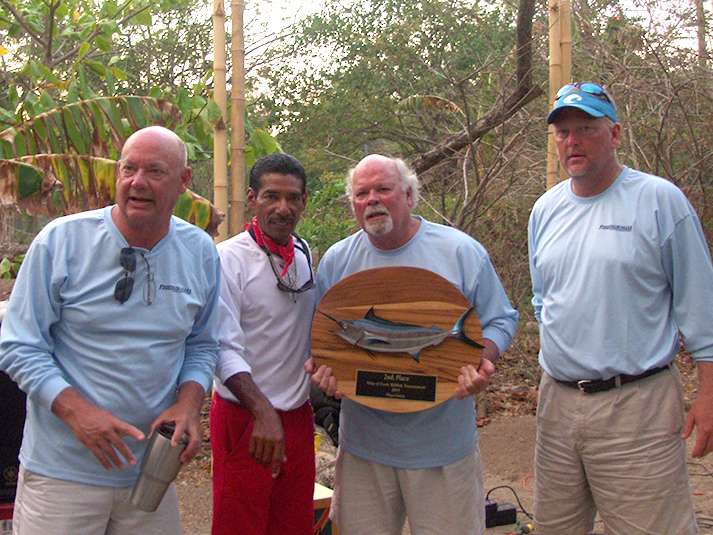

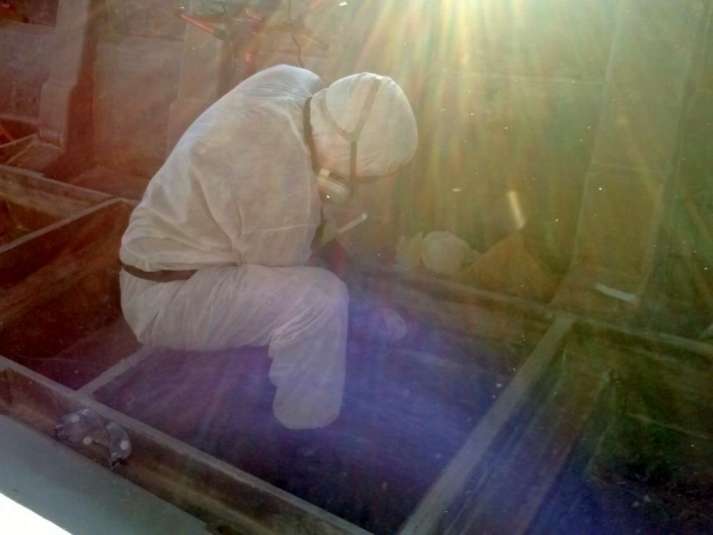

In these pictures Craig Sutton, Captain Jack, and Craig Jr. are inspecting the currently installed inboard powerplant.

We plan on selling this motor soon and converting this hull for outboard Yamahas.

This boat is in technically sea-worthy, but the soft floors and rusted bolts are a sign that a full refit is in order. Fortunately, the core pieces are in place and the majority of this boat’s needs are time and energy-based rather than costly price-wise.

Craig negotiated a fair price for this boat and we were pumped to throw in a week in Nosara in exchange for a price break. We look forward to getting this boats prior owner Earl Newton down to our little slice of paradise either this year or maybe sometime next year…he may even get to fish on the Discoverer!

April 14, 2012 – Day 4

Shortly after the glow of finding our new project hull wore off, the team had to address some very tangible obstacles. First off, we had no facility to store this boat nor a boat trailer capable of hauling it.

Even if we could haul it, the flying bridge on this boat stands at 26 feet. We will modify the tower to fold down into the cockpit so we can trailer this boat through the narrow winding roads around Nosara, but as she sits today the top is permanently erect.

Here’s what we can surmise about the Slick Cricket as she was purchased. This is a 1982 T-Craft 30 foot hull with a Cummins B Series Diesel inboard powerplant backed by a TwinDisc Transmission; this vessel was formerly flagged as the Miss Jessi until 1994 when this high-end motor/trans combo was installed.

The rod holders, rub rail, and other through hole fittings are secured with wood screws rather than through-bolts. Virtually none of these important fittings have 5200 sealant in place making this hull a potential sponge of water intrusion.

Also all of the marine fabric throughout the boat is mildewed and rotted so there will be significant sewing needs. Lastly there is a ton of layout changes in store from the rod holders to the fuel fillers…everything must go!

Basically this boat feels ‘slapped together’ and presents a different challenge from our last boat build. The Wanderer was a tight vessel when we began the rebuild; conversely the Discoverer must restored to a level of strength and quality that she has never known.

This seems like a good time to discuss the most chronic obstacle we will be facing on this build: We have virtually no money for this project.

The revenue generated by FishingNosara and Nosara Paradise Rentals barely covers the overhead, maintenance, staff and expenses inherit in running a resort in Costa Rica.

The reason we are building another boat is not that we have $100,000 burning a hole in our pockets, but because there were too many times this last season where we had to turn away clients because the Wanderer was already booked. Though we predict that the Discoverer will be a success it will not begin generating money until she is in the water.

Why am I telling you this? Well, if you want to see the perfect way to do boat work in a perfect shop with an unlimited budget and all the right tools then you may want to look elsewhere.

The FishingNosara build team consists of car mechanics, handymen, auto detailers, computer nerds, and other oddball characters and we build boats with hand tools and guts.

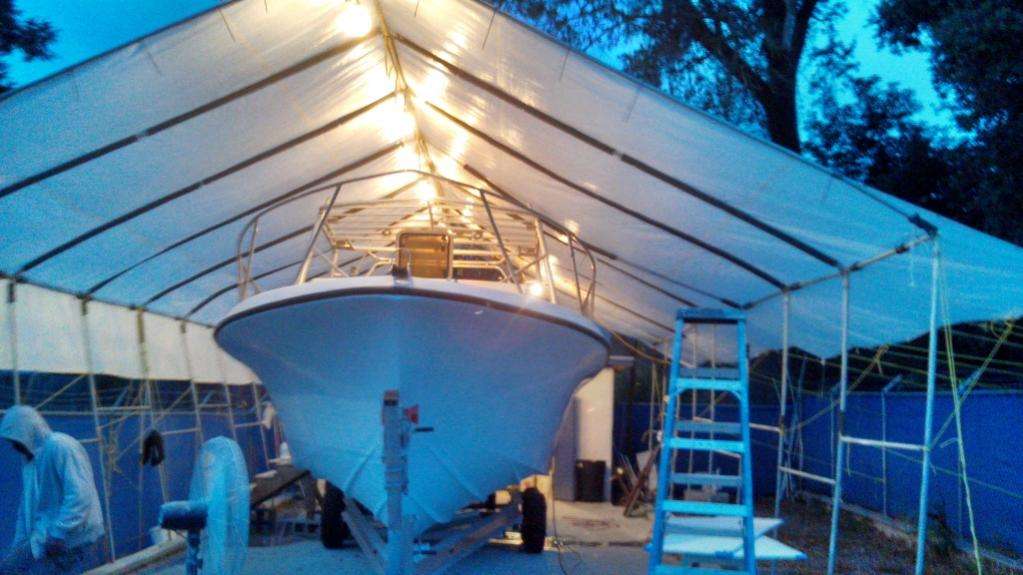

Over the last 5 years we’ve built world-class sportfishing vessels in a patch of dirt in the rainforest:

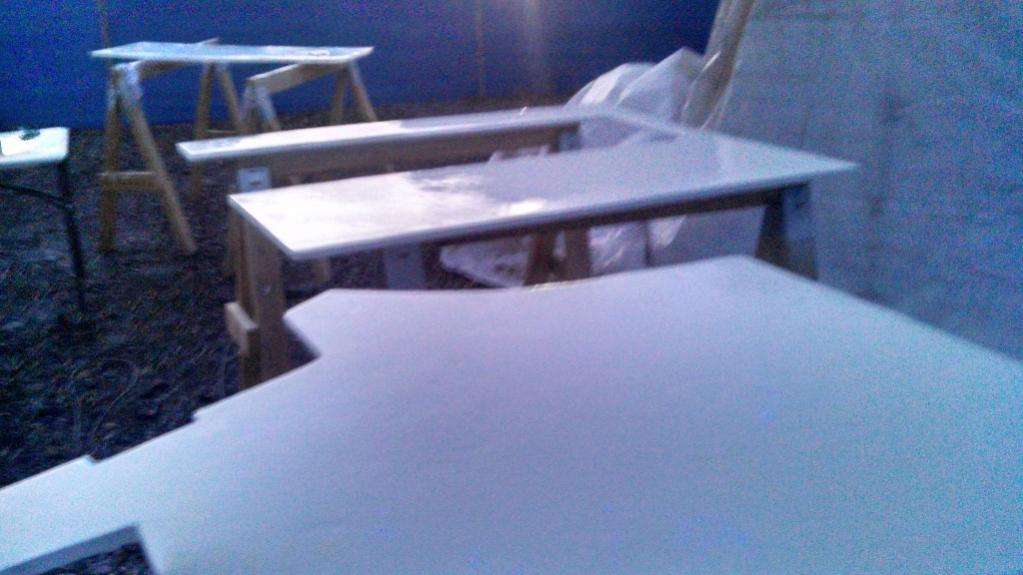

In an empty warehouse:

and this time we’re doing it in the backyard:

Naturally you can take away lots of boat building knowledge from this project and hopefully it helps you on your own boat projects. However it is our hope that all marine enthusiasts can draw inspiration from our commitment to hard work and creativity in overcoming obstacles rather than just throwing money at them.

In that spirit our good friend Marcus over at Ft. George Island Marina came through for us huge. He offered us a slip for the boat in his warehouse, use of their fork lift, and space in the yard to knock out the first phase of the project.

We did him a favor by tearing out all the moldy fabric so we wouldn’t make a mess of his facility.

Marcus tucked her into her slip and we all slept a little better that night.

The Discoverer was safe and sound, and we begin to search for a boat trailer and a permanent home for our new prize.

May 8, 2012 – Day 28

Matty and Captain Jack have really bad luck when it comes to rainstorms during FishingNosara projects. Let’s check the highlights:

Loading 10 golf carts into a container with only a pickup truck and one set of ATV ramps? Freezing rain.

Building a pallet with all the gear for the Adventurer? Hot muggy rain.

Pulling the tower off of the Discoverer? Lighting storm with tons of rain.

Unfortunately we didn’t get many pictures of this deal since Marcus was boldly defying logic by operating the forklift in a lightning storm; I love the guts on a guy who says, “The radar says we gotta shut down in 10 minutes…I think we got time!”

You can tell by the rain slick on the floor that we barely made it in time. It’s too bad they don’t put forklift driving in the Olympics because Marcus would bring home the gold every time.

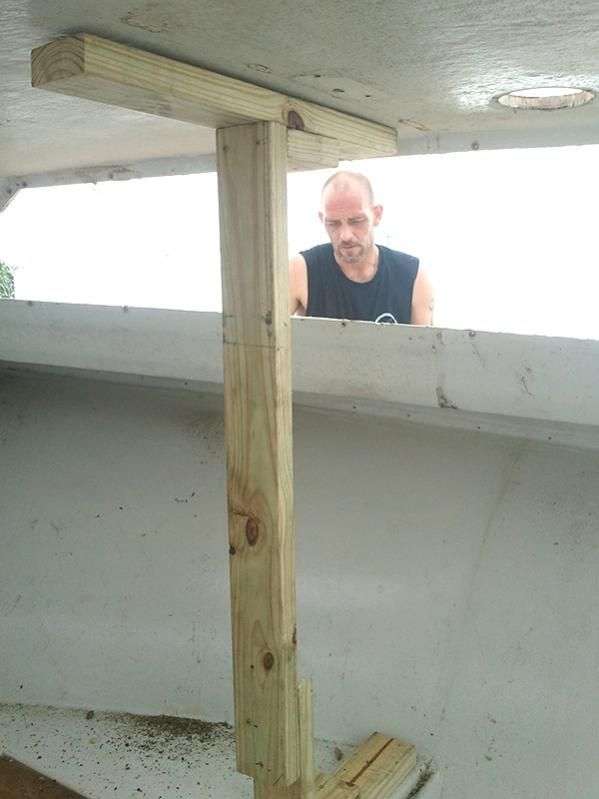

Captain Jack and Matty utilized the forklift to hold the tower up while they built a pallet-style support for the tower to rest on. This level platform will be the canvas upon which Craig Jr. executes his welding artwork so it needs to be strong and keep the tower square.

Once the rain cleared up we used a borrowed trailer to haul this monstrosity back to our shop. We’ll be setting this aside for a while as we continue to seek out a buyer for the inboard motor and settle on just the right trailer for this boat. For now we are one step closer to getting this boat on the road!

June 15, 2012 – Day 66

Enjoy the inaugural episode of The Discoverer Project. We will be presenting these video vignettes of our progress as often as possible as the Discoverer takes shape. No phony actors or multiple takes here folks, just real guys taking real risks to make a real dream come true.

In this episode we rip the motor from the hull and deliver it to our buyer. The proceeds from this sale are going straight to Magic Tilt Trailer and we expect delivery of our boat chariot in about 10 days.

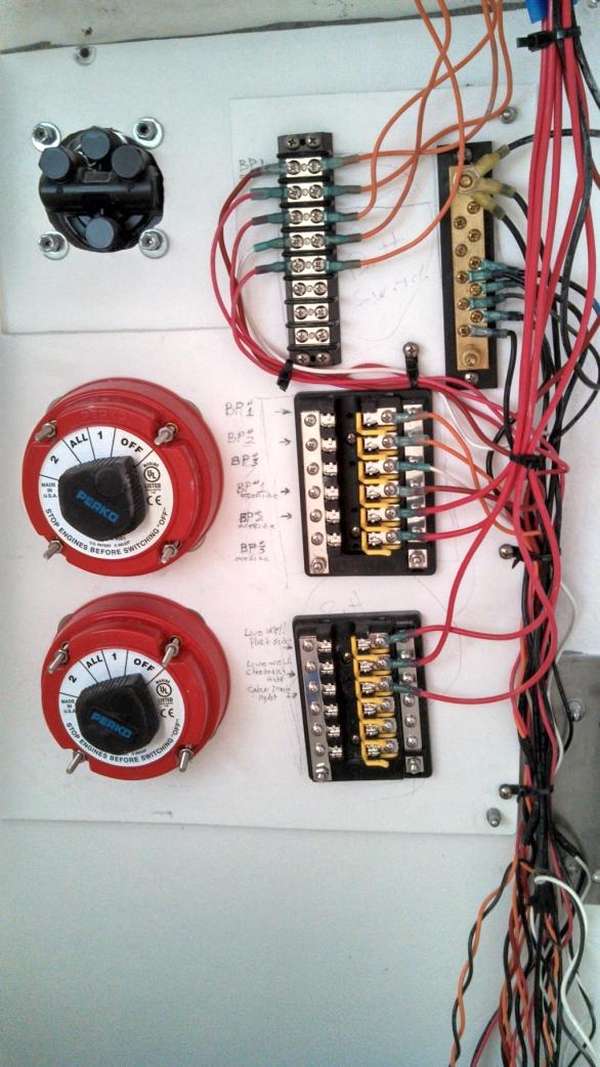

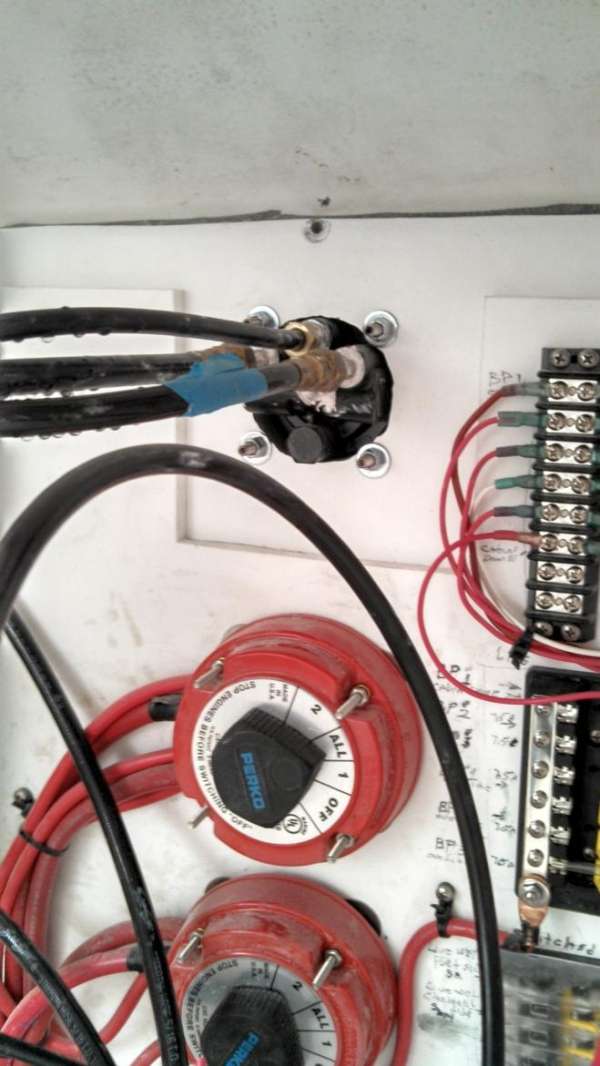

July 15, 2012 – Day 96

August 12, 2012 – Day 124

Howdy all. Work continues on The Discoverer Project as we strip all of the thru-hull fitting and other metal from the hull. The idea is to have a totally naked hull with most or all of the holes filled in before we paint.

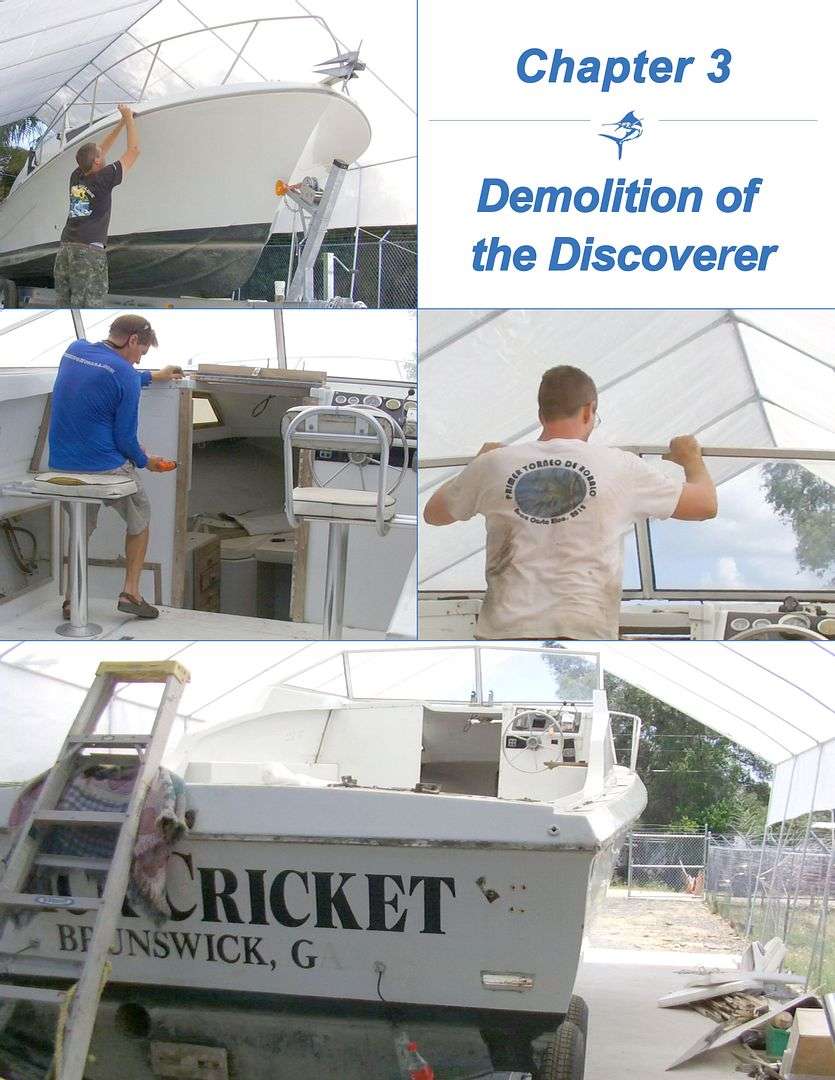

Episode 3 will detail the demolition process, but for now take a gander at these pictures as we stake up the cabin then remove the partition walls.

We will use these old dividers as patterns for new partitions which we plan on making out of 3/4in Starboard. This will save weight without sacrificing strength.

Jack has been busy cutting off the top layer of fiberglass on the nose and scraping away the old rotted wood underneath. The jacklegs who put this boat together last time got cheap and didn’t use any 5200. The soupy, muddy condition of the ‘wood’ proves once again how valuable that little white tube can be.

Craig and Jack are just beginning to figure out how best to secured our new dancefloor of marine plywood to the nose of the Discoverer. We are using this thin board as a beginning template, but we’ll wait and see how this elements turns out.

Episode 3 should be posted sometime this week, until then we welcome your comments on our progress so far.

Florida Sportsman Boat Building Forum

August 24, 2012 – Day 136

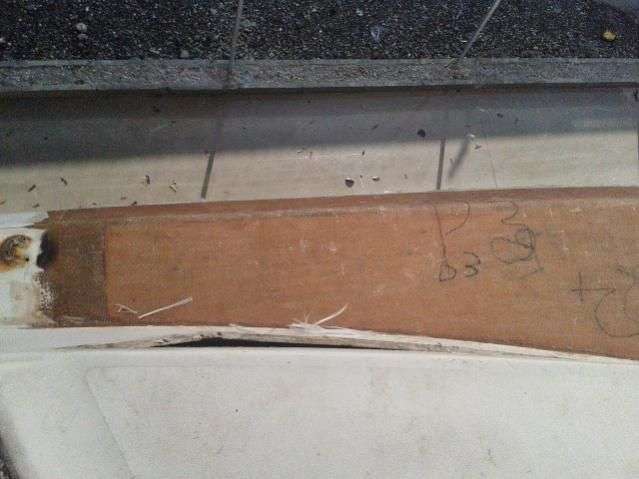

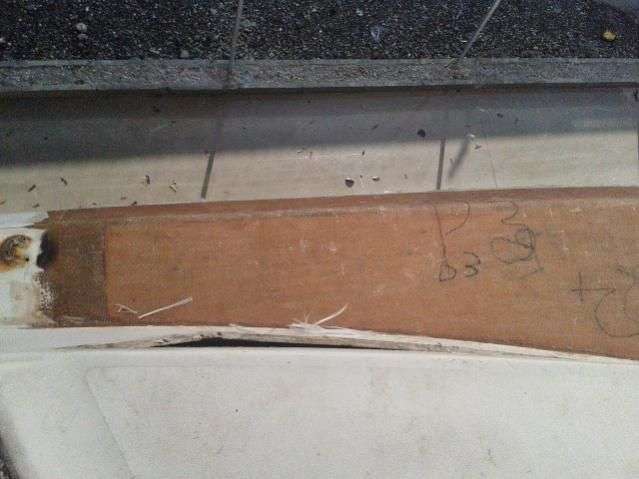

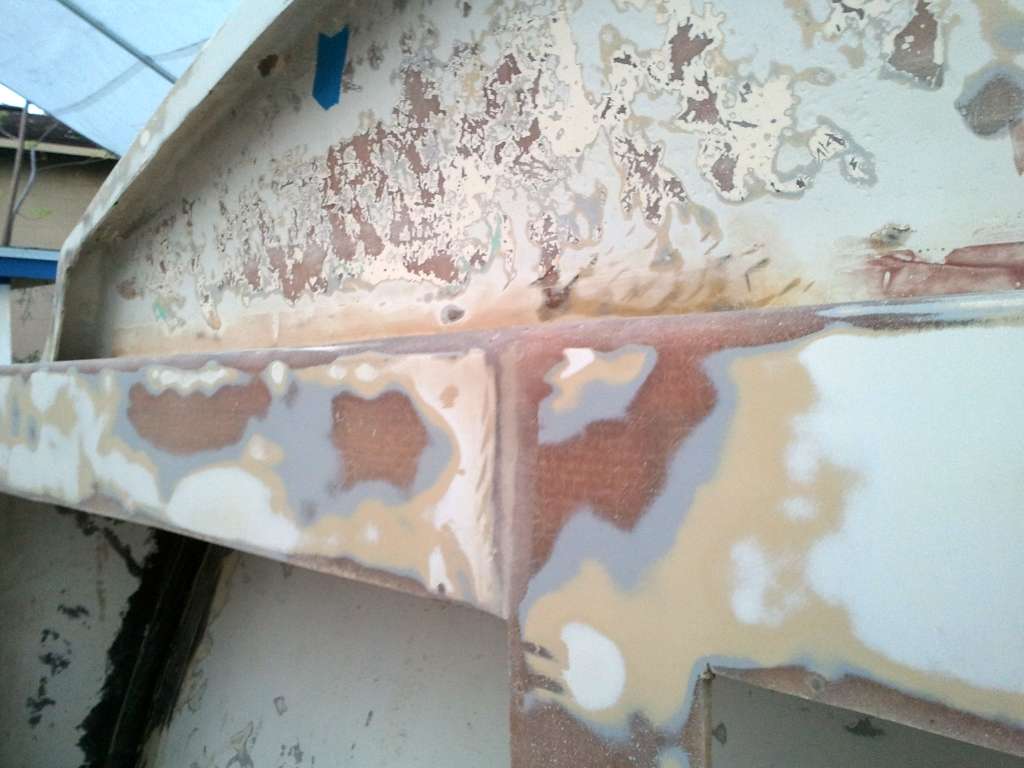

Craig has made steady progress on the nose job for the Discoverer. So far we have got the top layer of fiberglass off and have discovered that the ‘wood’ has rotted away to the point that a full replacement is necessary.

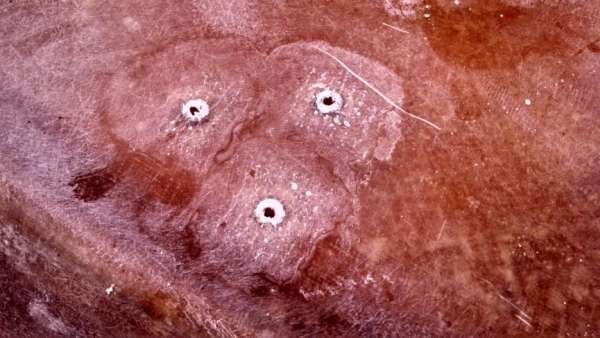

Take a look at the underside…there is no way that this soft floor would last for any length of time. The little cubes of wood are the random pieces that did not rot into oblivion, so this image should give you an idea how much slop was sandwiched in the fiberglass of this boat.

Our goal here is to fabricate a new front deck section out of 3/4′ marine plywood and fiberglass it in place of the old rotted floor.

Jack and Craig made a pattern out of butcher paper, then transferred the pattern to a 1/8″ piece of pressboard (See previous post). The press board is a rigid enough that we can grind on it like a piece of wood to make it fit the hole; once fitted we can to the cut ‘for real’ on the expensive plywood.

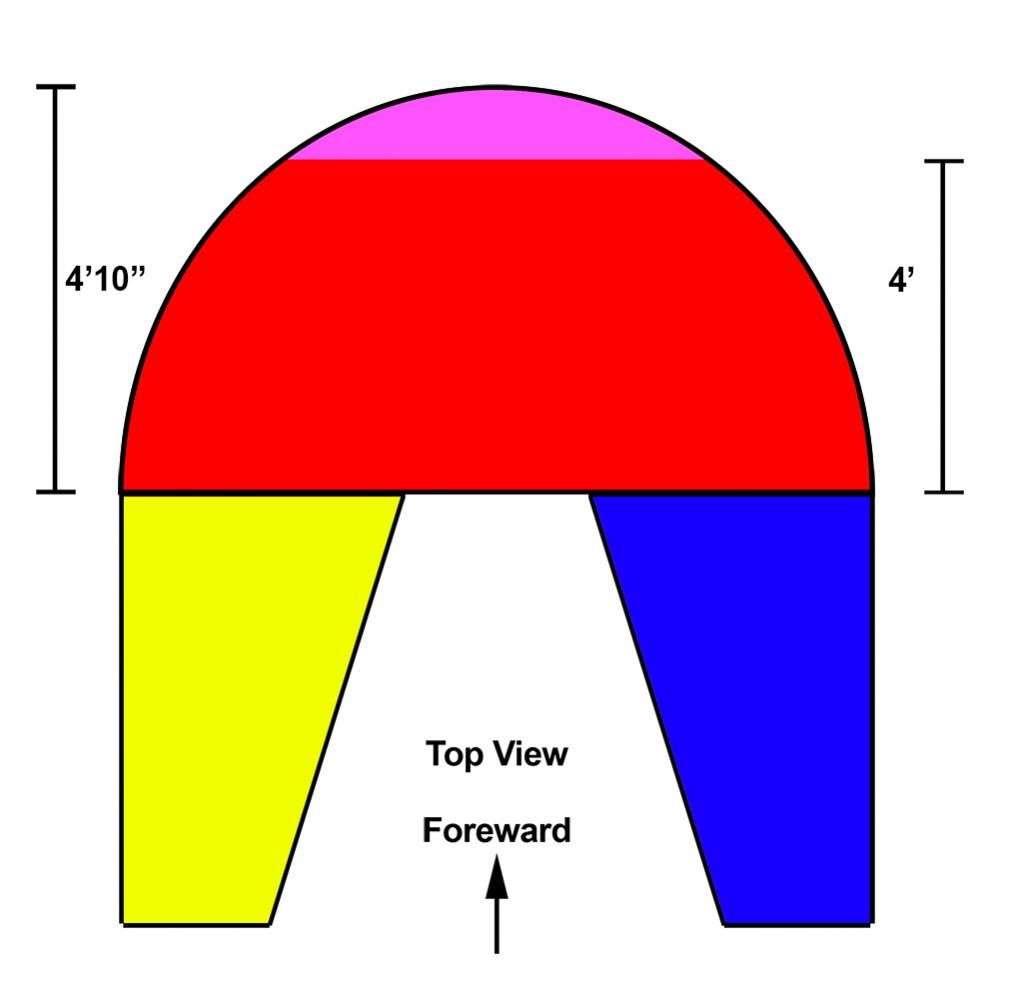

We discovered a problem immediately when we completed the pressboard mock-up. The tip of the nose is 4’10” from the base of the cabin, and as you may know plywood tends to come in 4′ wide sheets.

You can see in this graphic that our only option would be to scab in a 10″ wide piece to round out the nose (purple) and some how retain the strength of the wood in this particularly vulnerable point of the boat…we moor our boats so the nose anchor pulpit has to be the strongest part of the boat (See last year’s Wanderer repairs in our Off-Season Maintenance blog post to see what happens when the nose isn’t sturdy)

Amazingly the guys at Hood Distribution tracked down a beautiful 5′ x 10′ piece of marine plywood which makes this job about a million times easier. Now we can build the nose out of a single piece which will make this nose drastically stronger and the install less of a headache.

Craig transferred the pattern to the marine plywood and cut the rough shape with a jigsaw. Then he sculpted the wood down to form with an air powered disc sander armed with 180 grit paper.

After a quick test fit on the boat, Craig continued by tapering the underside of the deck to mate with the tapered edge we created on the hull. The idea is to make a clean mating surface where the wood and the fiberglass transfer weight between each other with as much surface contact as possible.

The final step was to flair the flat edge that mates to the cabin. Craig removes about 1/4″ of wood and takes care to make a smooth bevel at the edges.

We want to leave some flexibility for Charlie our fiberglass expert to do a final round of grinding before fitting this piece. Still we are pretty excited about the progress so far on this new dance floor and are looking forward to laying some down some coats soon.

September 10, 2012

Wow time flies when you are having fun and the FishingNosara Build Team has split up to double the fun. Craig, Craig Jr., and Matty are in Nosara right now overseeing the first major refit of the Wanderer. After 600+ trips over three years of excellent service, our flagship is getting a full strip down, re-prime and re-paint as well as some corrections to design flaws and construction errors that have sprung up over the years.

Look at Captain David and Mate Carlos getting after it! Grinding off bottom paint SUCKS and all the goggles and facemasks in the world can stop the micro shrapnel damage and the itching that follows. This is the hardest work we’ve ever demanded out of the boat crews and they are gritting there way though it; still I’m sure that they will be happy to get back to fishing.

We are currently on day 4 of 13 for this project and will have a full update in the September Fishing Report due out in mid month.

Back at headquarters we have Captain Jack Weinmann and Captain Charlie Keen up to their elbows in fiberglass as they give the Discoverer a strong front deck to replace the nasty mess we inherited (See last post). Now we have chronicled Jacks boat building prowess at length (See all Jack related blog posts) however Charlie is a newcomer to the build team but not new to the FishingNosara family.

We have sponsored Charlie in the El Cheepo Sheepshead tournament and worked closely with his auto body repair shop that happens to be situated about 300 feet from the Discoverer shop. This guy paints about 8 cars a day, runs a tight boat of his own, and recently found time to build an operational hovercraft.

Still Charlie has some misgivings about the size of this project and he relatively small scale experience with fiberglass construction. To me fiberglass work is like black magic and the fact that it is even possible is spooky and amazing. You hear stories about temperature and humidity screwing with the hardener/resin ratio and then hear other stories where an improper mix causes a boat fire and you kind of wonder how smart it is to be screwing with this stuff.

If there is one this that can be said about The Discoverer Project is that there is a lot of outside advice, both solicited and otherwise, that comes through big for us. Our buddy Chappy turned us on to a sweet product called Woven Roven which is essentially a fiberglass mat as thick as your grandma’s afghan rug. We learned from Charlie that epoxy resin is the way to go for high-load areas like a deck versus polyester resin. Even though epoxy is much more expensive that poly in this case it is worth every penny.

Any comments anybody has regarding fiberglass, resins, fillers please chime in on the comment board at let us know what we don’t know, which is quite a bit.

September 6, 2012 – Day 149

We put down a thick layer of epoxy resin on the underside of the new deck and on the cleaned scraped layer of fiberglass (ie the backside of the cabin ceiling). We added a layer of 2oz. fiberglass mat (standard, not he roven) then sandwiched that matte under the wood.

To pull it all together Charlie shot wood screws through the top into plywood blocks that an assistant was holding below decks; this squeezed the fiberglass/epoxy/plywood sandwich and hopefully pushed out any air pockets or bubbles.

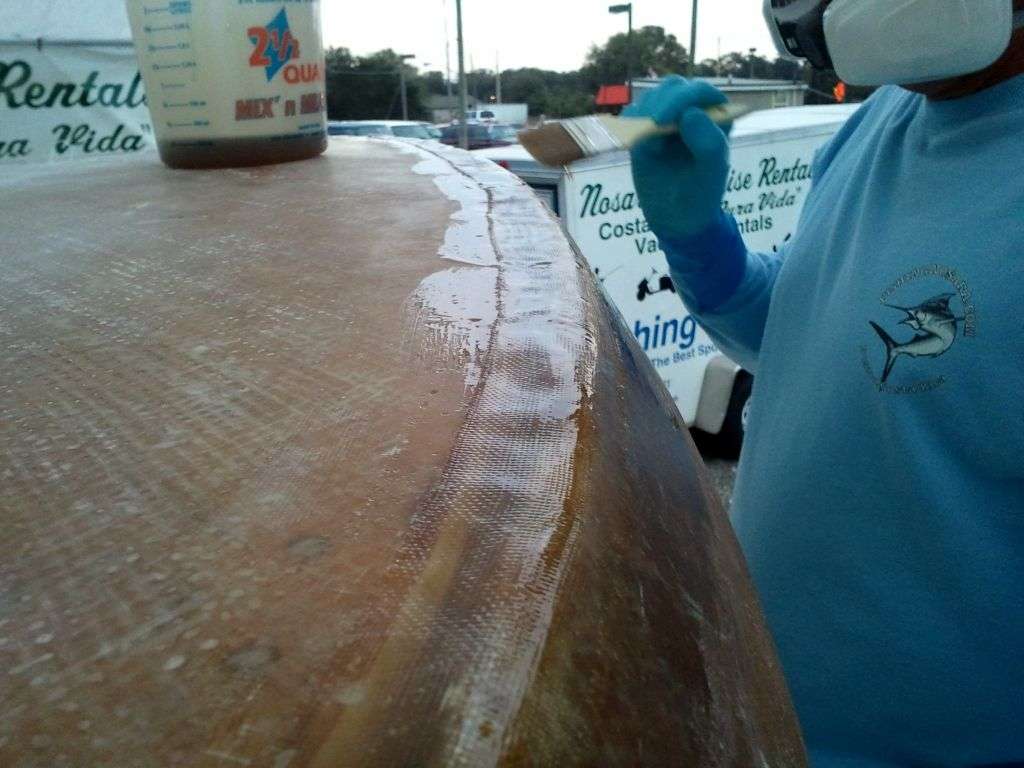

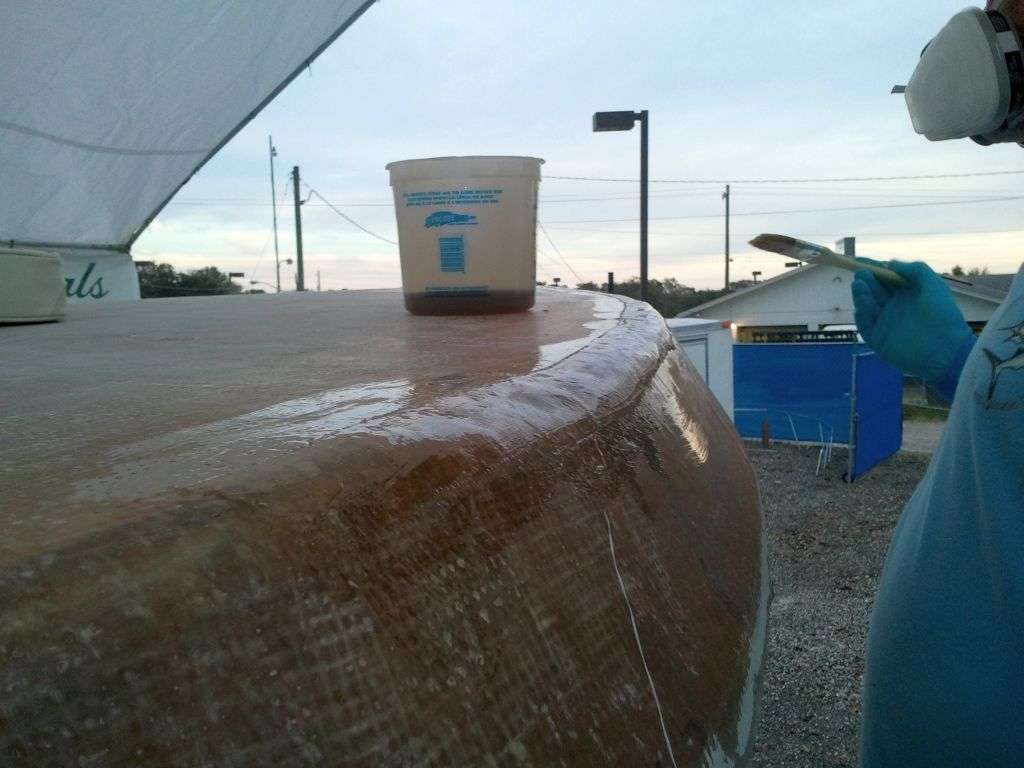

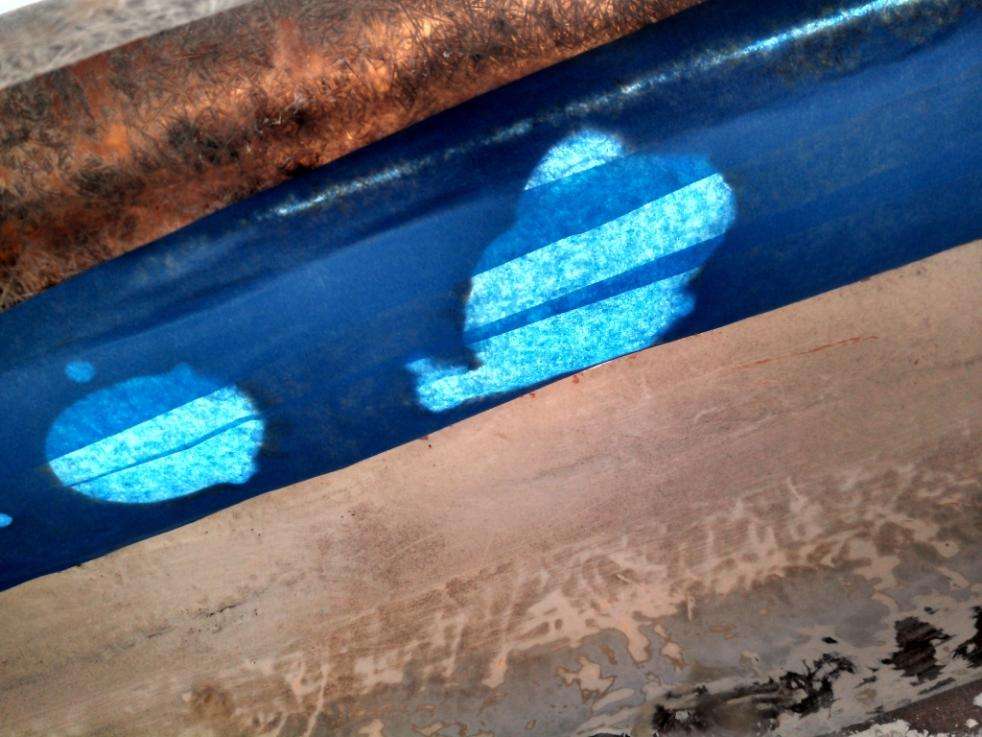

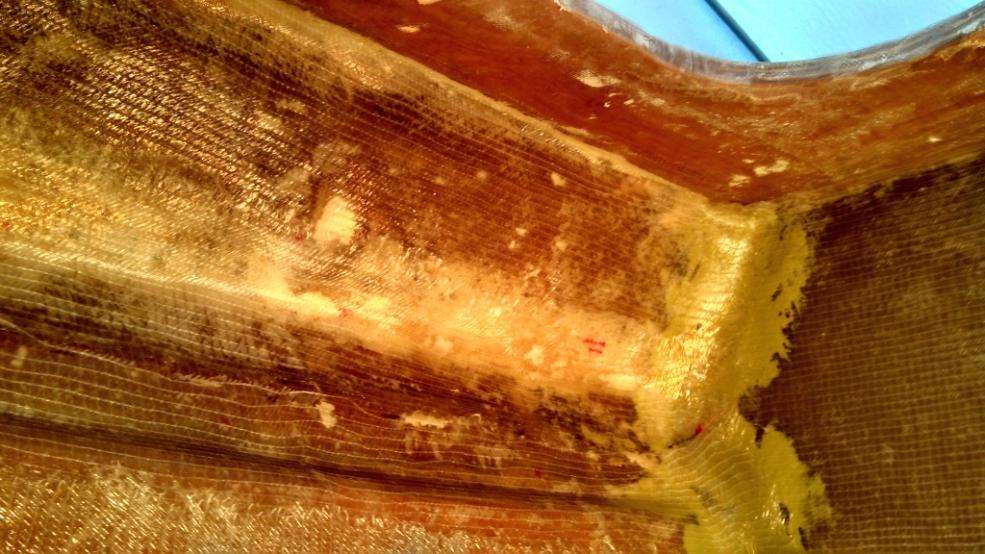

Most recently Jack and Charlie installed the first two layers of Woven Roven and the pictures tell the tale on this stuff:

We hope to have the deck done soon and then move on cutting up the floor and pulling out the gas tanks. I feel confident in the deck and think that it will be easy to apply what we have learned on the much less geometrically challenging fuel covers.

Jack and Charlie have kept the pedal to the metal while the rest of the team is rehabilitating the Wanderer down in Costa. The shop in Florida is humming with the songs of DA sanders and the air is thick with the syrupy stench of fiberglass resin.

The boys finished off the second coat of Woven Roven and they report that it is sturdy as a brick.

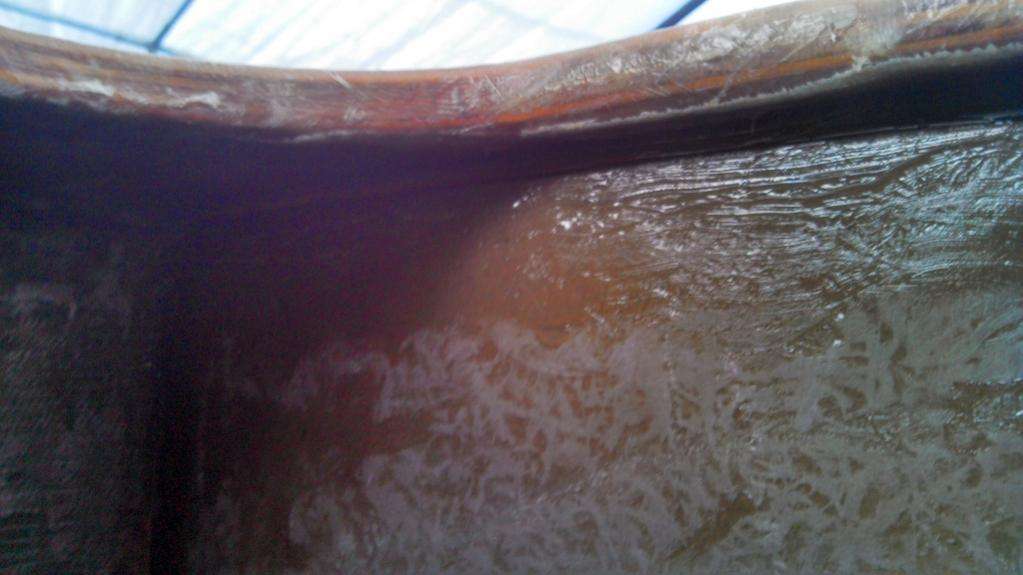

We are really pleased with the fit of the marine plywood deck pieces. All of the pattern transfers worked perfectly from the white paper all the way to this finished 3/4 inch cut. Here is the finished assembly after being glassed into place:

While they had the carpentry and fiberglass tools out they went ahead and took care of the former exhaust port in the rear transom. They fared the surrounding fiberglass to accept the topcoat and cut a circular plug from the marine plywood scraps. Now this area is as strong if not stronger than the rest of the hull.

The front deck of the Discoverer is firmly in place and sturdy as a brick Check out these results:

Charlie Keen is a fiberglassing fool! He has parlayed the momentum established from the front deck piece into a full-on resin renaissance. He has filled almost all of the holes left behind by the old water pickups, the propeller shaft, and the inboard exhaust port in the transom.

Clearly the prop hole (above, the odd shaped hole to the left) is a difficult patch due the the extreme angle of the hole, but Charlie made this patch look like a walk in the park.

During the stripping process Jack removed the transom exhaust portal with an angle grinder and did a good job of leaving a smooth hole for Charlie to patch. Take a look at the step by step process:

A wood plug is cut for the hole and the surrounding area is ground down to accept the plug, then the first of several fiberglass mats is applied. Notice the holes punched in the weave which allow for trapped air bubbles to be pressed out of the wet resin.

They sand the finished fiberglass lightly so it will accept a covering patch of resin mixed with body filler. This completes the repair and this area is now an indistinguishable part of the transom. After priming and painting there will be no evidence that this hole was ever there.

Jack took this time to catch up on some overdue trailer modifications. Remember that in Episode 2 of The Discoverer Project we had to slide a piece of plywood under the nose of the boat so that it would sit correctly on the trailer. Permanently fixing this problem requires lifting the boat off of the trailer and repositioning the cross supports. Here is a view from the bottom…not a great feeling being under a dangling boat, but with these mods complete the hull should rest nicely for years to come.

It has certainly been and exciting few weeks as the Discoverer begins to take shape. We look forward to reporting on more good progress soon.

September 29 – Day 172

Well the team is back together as Matty, Craig Jr., and Craig Sr. put the finishing touches on the refit of the Wanderer and made it back to Florida last weekend. We finally got our hands dirty on the Discoverer again after a barnstorming trip to Tampa for the Florida Sportsman Expo the day after we got back from Nosara.

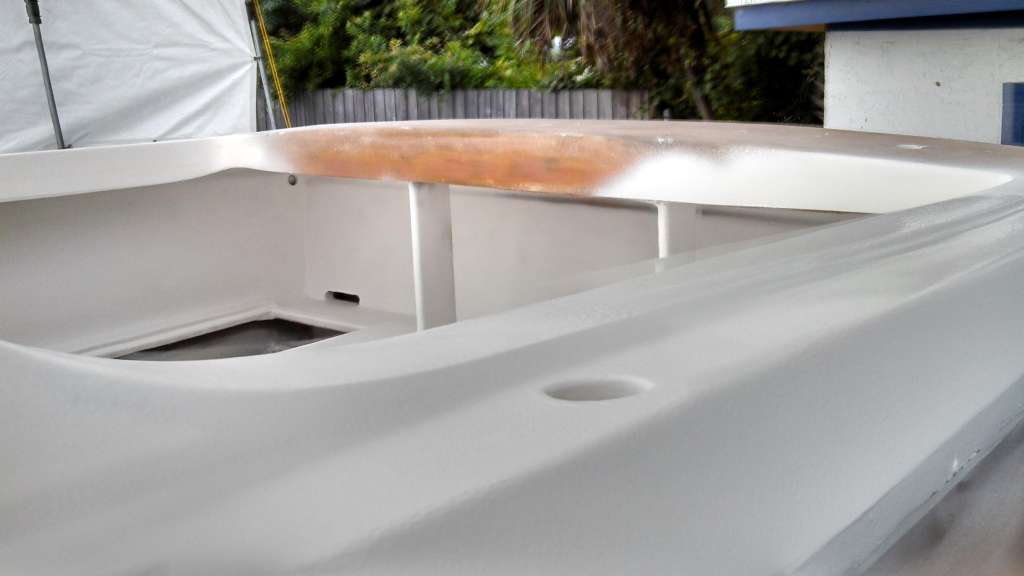

So through the hazy fog produced by jet lag, culture re-acclimation, and soothing wives/girlfriends angry with us for always being gone, let’s take a look at the current state of the Discoverer:

You can see that the DA sanding of the hull is moving along nicely, and we almost have all of the shiny spots roughed up. One more day of sanding and she will be nearly ready for paint.

Charlie Keen has worked his magic on all of the holes in the rear transom as well as the pickups under the boat; last post we mistakenly reported that the boat was being lifted on pipe jackstands when in fact those stands were holding in the fiberglass plugs.

Notice anything missing in that last picture? If you said “half of the floor that covers the fuel tanks” then you are correct.

We weren’t sure the size or conditions of the fuel tanks until Craig and Jack started cutting, and what we found is shocking. This pair of 120 gallon tanks are the largest I’ve ever seen in a T-Craft and getting them out will be a challenge.

Notice that in the rear these tanks butt up to the transom, and up front they are covered by the side benches. These benches are fiberglassed directly to the hull so their ain’t no removing them except via the sawzall. On the Wanderer the 100 gallon tanks lifted right out through properly cut access panels; on the Discoverer we will have to get more creative.

Our working plan is to drain the tanks then cut them into small enough pieces to remove.

Afternoon Update:

Just ran outside and shot some up-to-the-second pics. Here is the aforementioned jackstand that is holding in the bottom fiberglass plugs:

Here we see the starboard side bench cut out to allow for removal of the tank. This cut killed our cut-off grinder, so it’s off to the hardware store to buy another…bummer.

October 1, 2012 – Day 165

October 6, 2012 – Day 179

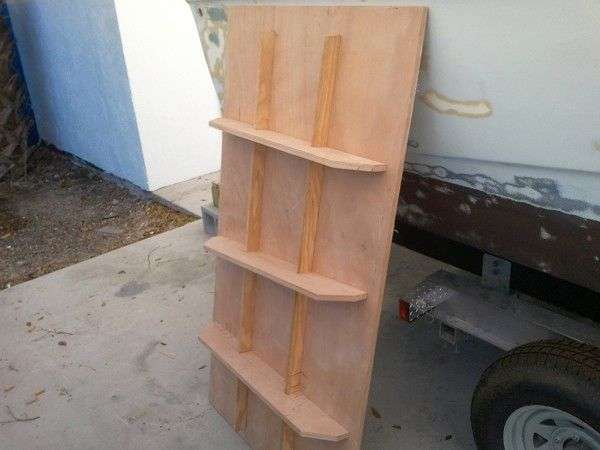

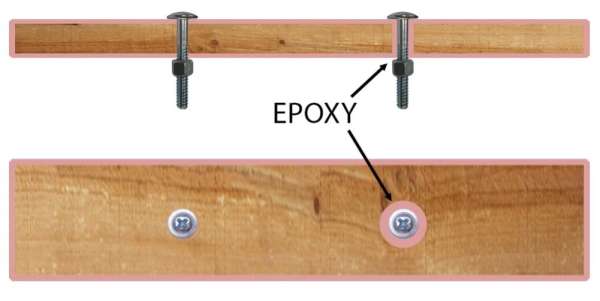

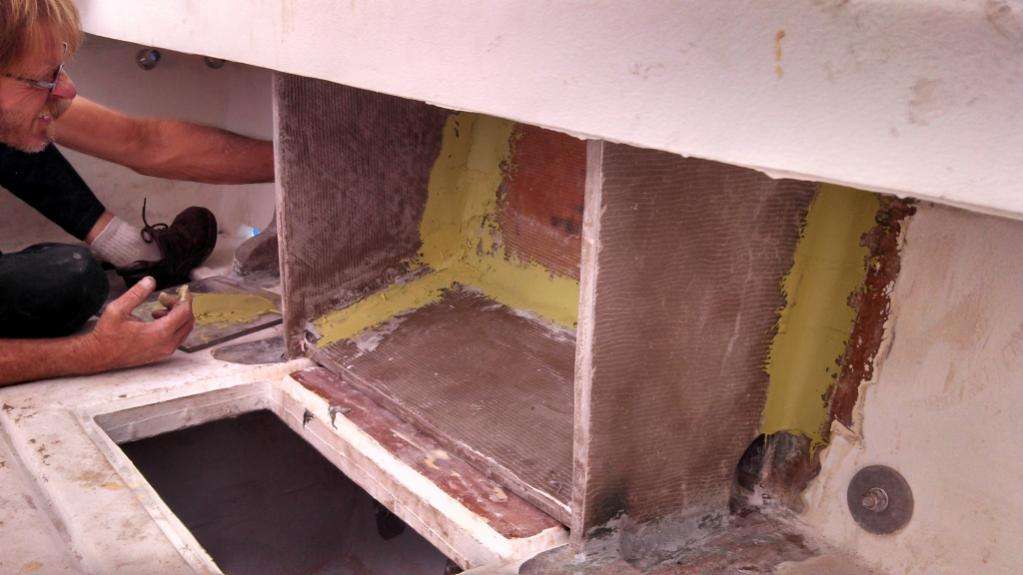

It’s been a dirty week of work on The Discoverer Project as we moved below decks into 20+ years of diesel-flavored sludge and muck. Charlie has taken the next step in fabricating the floor by installing these 1″x2″ runners along the edges of the fuel tank compartments and the center compartments.

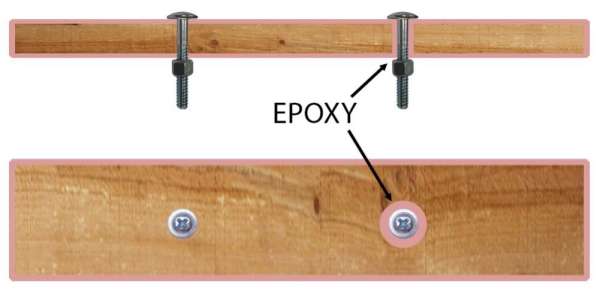

These will be encapsulated in fiberglass to ensure that they are watertight and Charlie has an idea that is common among expensive custom boats: in every spot that will receive a screw, we will drill out about a 1 inch hole and fill the hole with epoxy resin. This way the wood never gets penetrated by a screw.

It’s a little tricky to line everything up, so stay tuned as we progress on this element.

In the last post we removed the deck plates over the fuel tanks, and to our surprise these tanks are much larger than we anticipated. The tanks run flush to the transom and extend all the way forward, almost to the seat pedestals. We estimate that each tank holds 120 gallons of fuel.

Jack began the delicate work of cutting an access panel into the top of the tanks to allow for our friends at Independent Waste Oil get their sucker hose into the tanks.

Remember on every aspect of the fuel tank work everything must be done twice.

Handy trick: Raise up the front of the boat as much as safely possible while draining the tanks; this ensures that a maximum amount of sludge and fuel make it out of the boat.

The Discoverer will feature aluminum tanks similar to those on the Wanderer. Aluminum tanks are far more lighter and durable than their fiberglass counterparts, plus by having them fabricated to fit we free ourselves from the existing dimensions of the holes in the floor. We are very pleased with the tanks built for us by Atlantic Coastal Welding in Jacksonville on the Wanderer, so we plan on using their services again.

However before we start designing the new tanks, the old ones gotta go!

This is tricky because of the limitations of the situation. First off, you can’t use a sawzall or any other ‘deep-cut’ tools because of the tight clearance between the bottom of the tanks and the outer hull; one slip and we are patching a gash in the side of the boat.

Also, you can’t generate too much heat because of the low flashpoint of the leftover diesel fuel mix, so forget about torches, jigsaws or body saws.

The only tool for this job is a low-RPM cutoff grinder borrowed from Jack’s automotive toolkit. Jack kept the RPM’s low and made long scoring cuts rather than digging in and dragging.

This is an arduous and nasty process, but Captain Jack ain’t scared of a little grinding dust. In the above picture he has already cut away the 3/4″ lid of the tank and proceeded to cut out the horizontal baffles. Here is a close-up of the baffles:

Jack and Craig then cut horizontal grooves into the bottom of the tank (carefully!) so the tank could be removed in sections. The tank is way too big to come out in one piece…quite frankly I think they built this boat around the tanks!

Even with the sectioned removal approach, we battled a layer of foam insulation that held the tanks in place. No exotic way to knock this out; just the old fashioned prybar and balls.

With the tanks gone, Charlie can begin fabricating the new covering boards for the forthcoming aluminum fuel tanks. Meanwhile we will begin cleaning our sanding dust and wiping the hull with acetone. It won’t be long until we are prepping for paint and then it is off to get the transom installed. Stay tuned as we continue work on The Discoverer Project.

October 18, 2012 – Day 191

It’s been another crazy week on The Discoverer Project as we have moved ahead with sub-floor fabrication in the cockpit. Craig and Jack made a heck of a mess grinding and cutting out the fuel tanks (see last post) so the first step was to clean up the evergrowing mess of fiberglass dust and wood shavings.

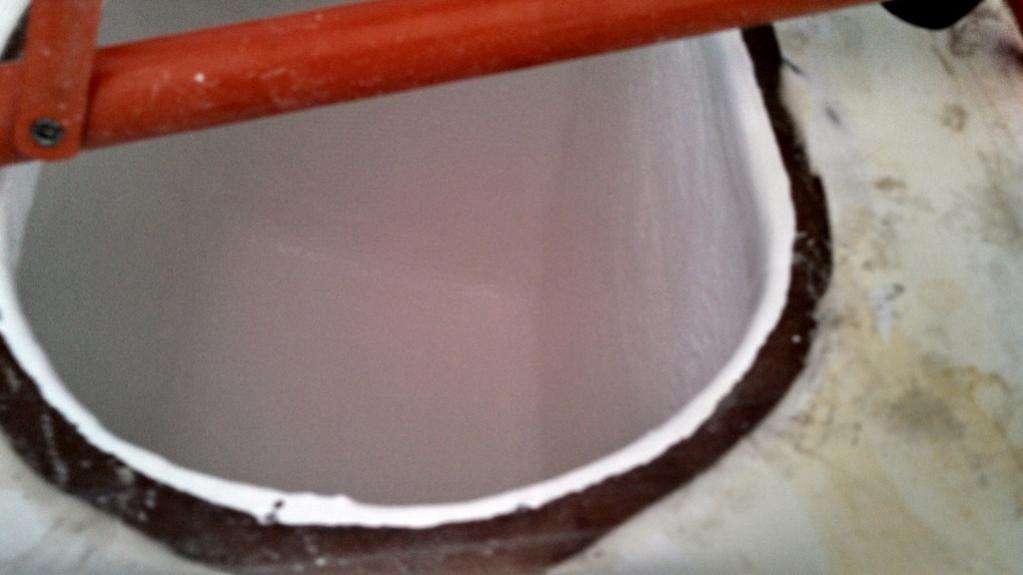

Charlie has already cut replacement rails for the holes in the floor and now begins the process of glassing them into place. The red clay-like material in the foreground is actually millions of microballoons that (when mixed with hot fiberglass resin) turn into a putty that can fill gaps much better than fiberglass alone.

Charlie laid his first round of fiberglass tape around the two large central openings, then cut six pieces of marine plywood that will be encapsulated in glass and eventually become the new floor for the Discoverer

That night disaster struck as a fog bank rolled through Jacksonville and wrecked havoc on the fiberglass resin setting up. When Charlie showed up to check his test section of fiberglass the whole piece detached.

There is no avoiding moisture-related setbacks when you are working on a boat outside in Florida. Fortunately we are getting to the time of year when the temperature and the humidity are on the decline and hopefully we can get through all of the fiberglass and paint work before the summer starts again in February.

On his second attempt Charlie achieved adhesion and could move on with enclosing the forward deck holes. Since the forthcoming fuel tanks are significantly smaller than the old ones we will fill this dead space with marine foam; you can never have too much foam in a hull.

The next trick up Charlie’s sleeve is to build a fiberglass arch intended to tie the fighting chair directly into the stringers. On the Wanderer we struggled with the best way to secure the fighting chair; not only must it withstand the abuse of reeling in 600+lbs. Marlins, any fighting chair gets grabbed alot by anglers and crew seeking balance. Sometimes the weight of three people are yanking on this thing so through-bolting it to the fiberglass floor is just not strong enough for us.

On that boat the solution was to screw a 3/4 stainless steel plate into the stringers horizontally. It did the trick strength-wise but weighs alot and is not very elegant. Charlie has proposed a dynamite solution with which we are quite happy.

This arch will receive another coat of glass that will fully secure it to the stringers, and once it does we will have a perfect spot to secure the fighting chair on the Discoverer. Speaking of fighting chairs, check out the rebirthed Wanderer chair:

First Mate Alex really outdid himself on this project. I can’t wait to see this baby in action come November 1!

Next up for Charlie is finishing the covering decks for the fuel tanks and running final surface coats of fiberglass to the cockpit floor and the front nose deck.

Meanwhile we are waiting for our fuel tanks to arrive and getting our ducks in a row for the upcoming month of hanging the transom deck and painting the boat. Stay tuned for more fun as it happens!

October 29, 2012 – Day 202

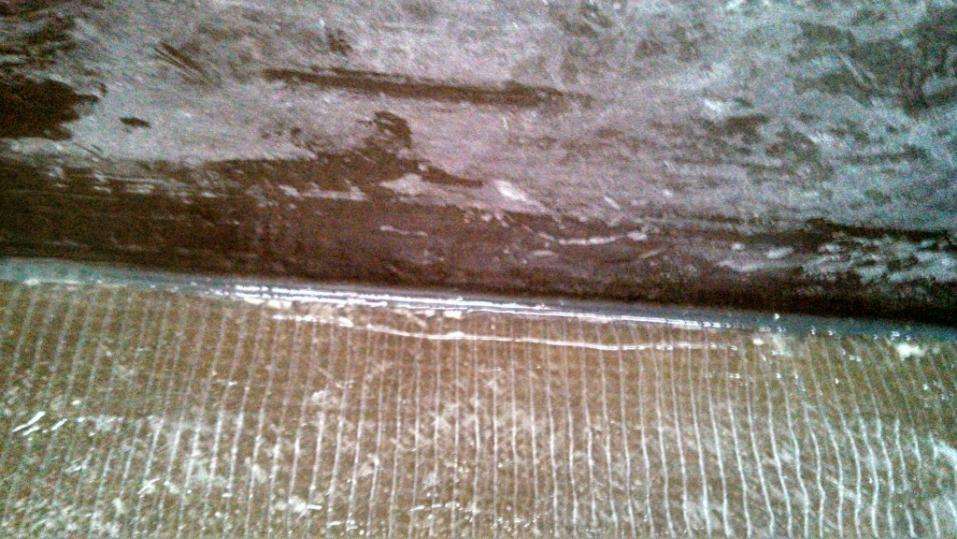

Another great week of fiberglassing for the Discover has come to a close and we are pleased to report that we are in the home stretch. Charlie got down to the finishing touches by finishing off the corners of the aft deck opening and securing the permanent cover to the floor. We use a flexible fiberglass woven tape for the edges of the openings and standard 4 oz. mat to encapsulate the deck covers.

Charlie will remove these screws once the fiberglass sets up and then fill the holes with epoxy. The screws are in place to ensure that the whole deck is under pressure so no air bubbles get trapped within.

Here is a finished corner after a full day of setting:

This cover is now a permanent part of the floor, but beneath the surface it holds a powerful secret; Charlie finished glassing in the fighting chair support arch and this trick installation will mate the chair directly to the stringers for maximum fish-fighting strength.

The next step is to prepare the removable floor sections. The fuel tank covers have already been encapsulated with fiberglass mat:

Lastly, check out the underside of the in-floor fishbox lid. Once fiberglassed this section will help with the rigidity of the hull and the boat as a whole. This piece should be pretty cool when it is completed.

We just returned from an excellent weekend at the Ft Lauderdale Boat Show and are primed to get back to work on The Discoverer Project.

November 15, 2012 – Day 219

November 16, 2012 – Day 220

Progress continues as we begin to finalize our new floor sections for the Discoverer. In these photos we see that the top and bottom of the new fuel tank covering boards are completely encapsulated in fiberglass. The next step is to apply layers of flexible fiberglass tape around the edge to finish the entombment.

The fiberglass tape is so useful because is it otherwise impossible to wrap fiberglass matting around corners without creating air pockets. Here is a close-up of this tape job on the underside of the new fishbox.

This solution is much more durable and elegant than building up layers of chopped strand or foregoing the mat altogether (sometimes called ‘hot coating’)

While the new pieces are curing safely under the tent, Craig and Charlie re-installed the shelving along the sides of the cockpit. These had to come out to remove the fuel tanks (see last post) and once the final tape layer is applied, no one will be the wiser that they were ever removed.

Most recently we removed the temporary screws that were holding the fighting chair arch and rear floor together as one unite. Now that the fiberglass has cured we can remove the screws and fill the old holes with epoxy.

You can see that Craig had to grind away the top coat around the screws to access the heads, so a final coat of resin with be required before prep sanding this area.

Charlie is almost done with the fiberglass work and has a few more holes to fill around the boat before painting begins. Jack and Matty are currently proceeding with prep sanding the front deck and will soon move to the rest of the hull. It is our goal to be spraying paint before the end of November. Stay tuned!

November 21, 2012 – Day 225

It’s Thanksgiving week and with all the talk of stuffing, and getting stuffed, etc. Charlie decide to ‘stuff’ some more holes in the Discoverer. As we rapidly approach the final prep sanding phase and look forward to applying paint, we keep finding more and more little issues like these that need addressing.

These holes along the top of the aft gunwale are a pretty straightforward fix. The fiberglass and wood are still sturdy this far above the waterline so the fiberglass is truly ‘plug and play’.

Up near the head was a whole different story. The pair thru-hull fittings were (Surprise, surprise) lacking any 5200 sealant so water has intruded around the holes. The damage extends about 4 inches outward from the hole so Charlie had to scrape out the damaged wood, stuff the crevice with chopped strands of fiberglass, and push the hot resin up to fill the void.

So far the inside of this pair of holes is all patched up and the outer layer is coming soon.

December 19, 2012 – Day 254

Sorry for the long layoff, but we’ve been super busy standing behind the sanding machine for the last three weeks. Matty has grown fond of his new Porter Cable electric DA sander and has been wearing out lots of 80 grit and 40 grit sanding discs.

During the sanding process we discovered a flaw in our front deck installation (see previous posts). The bulk of the deck set up perfectly, however some significant air bubbles formed on the outer edges of the installation.

Matty used a grinder to expose the affected area and to rough up the surrounding area to accept the repair:

Then Craig went around the area with a compressed air blower to clean all of the dust out of the crevices; any trapped sanding dust could create more air bubbles and put us right back at square one.

We mixed up a load of resin / hardener with a bunch of chopped-strand fiberglass for thickness, then Craig worked quickly to fill the voids before the material set-up.

Here’s a look at the finished application of the raw fiberglass material:

Craig followed up with a double-thick layer of fiberglass tape to secure the area and to provide a better surface to begin finalizing the curved lip of the deck.

The next day Matty came back with the sander and knocked down all the high spots to match the level of the deck. The low spots remain, and will be filled up to level by the forthcoming layer of resin and fiberglass mat.

We are getting close to finalizing all of the fiberglass repair and will be shooting our first layer of gelcoat very soon.

Clearly The Discoverer Project is gaining momentum as we near 2013.

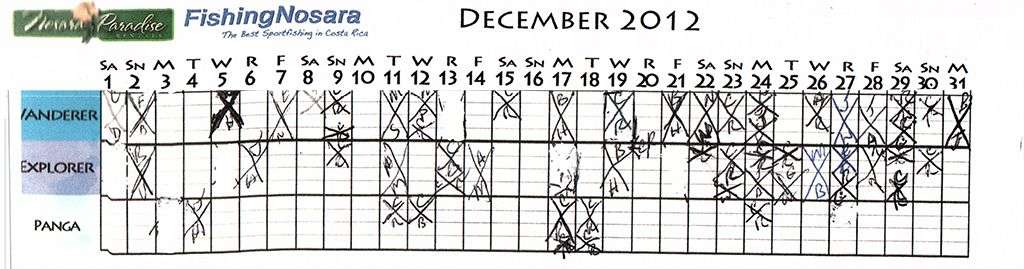

December 27, 2012 – Day 262

Craig rolls into the office the day after Christmas and throws the fishing calendar down on the table. “We need another big boat!” he exclaimed, pointing at the line for the Wanderer.

He’s right! A quick look shows the blue beauty fishing every single day except Christmas (and that wasn’t due to lack of demand) and clearly the market is primed for the arrival of the next great Costa Rican Sportfishing vessel. The only thing standing between the Discoverer and the blue water is about 1000 hours of labor and God-knows how many dollars.

Nothing to it but to do it, so Craig got back to work on the new front deck of the Discoverer. Here is how we left things before the break:

The high spots have been block sanded down to the same level of the rest of the foredeck, and the spots that are still shiny are lower than the surrounding level. Craig applies liquid resin / hardener with no additives (also called a ‘hot-coat’) to the low spots, then we add another layer of fiberglass tape over top of the resin.

The idea is bring everything up to the level of the foredeck, and if we accidentally build it up too much that’s no problem because we can always bring it back down with the sanding block.

After an overnight cure and some early morning sanding, Craig returned to repeat the process; there are no shortcuts when it comes to building up levels of glass like this, just lots of time spent on a sanding block.

Finally the entire deck is at the proper level! All that is left to do is a final touch with the block sander, then clean it up and add our final layer of chopped strand.

Here is last bit of this deck that will ever see the sunshine:

Craig is fired up to keep this thing moving so he began forming the chopped strand sections even though Matty had one more round of block sanding to go:

Meanwhile Charlie came around and added another coat to his hole repairs by the bathroom and the rear transom. He moves like a ninja and makes this stuff look easy, but trust us this is high-level detail oriented work:

We are stoked for the final coat of chopped strand and you know where to find the pics…right here baby!

“Thats a lot of work, I am curious to know if you have calculated the amount of weight you have added with all that glass and resin?

I am also wondering why you did not use non woven biaxial fabrics to save weight and improve the overall strength? You could have also used a light weight fairing putty to fill the low spots on the deck and skipped that final layer of matte.

It seems like you guys are doing more work than you need to but I will give you tons of credit for taking on the job. Good luck and keep them pictures coming.”

-Dave Meyers, Florida Sportsman Forum Senior Member

January 30, 2012 – Day 296

Hi Dave,

Thanks for the reply! You are totally correct that the approach we are taking with the nose seems extremely overbuilt, and common wisdom tells that a lighter nose / bow means a softer ride, better gas mileage, and less horsepower required to get up to plane.

We currently have a boat almost identical to the Discoverer in service down in Costa Rica and the front deck has been a constant source of concern in our specific application. We keep this boat (the Wanderer) in the water year-round tied off to a mooring point and last year a freak set of waves swelled into our harbor at Garza Bay.

The Wanderer incurred serious damage from this event as a rouge wave came over the back, filled the cockpit, and sprung the whole boat up on her nose. When it crashed down, here was the result:

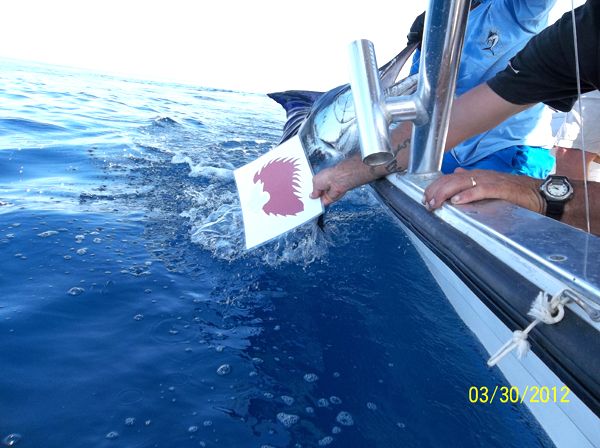

Also as a charter boat we have come to expect the unexpected when it comes to client behavior. Sometimes we have hardcore anglers want to sight fish off of the bow; other times we have 10 yoga students who want nothing more than to hang off the bow and look at dolphins:

The Wanderer has taught us the value of having a strong foredeck because the unexpected is always right around the corner for us. Read the details on the whole in-country repair process here: Wanderer repair – September 2011

As for the weight issue, we have a very short ride to the blue water (less than 6 miles) and never need to exceed 25 knots even during tournament time. With the Discoverer I figure we have added approximately 75 pounds to the nose so far and will probably end up just short of 100 pounds added by the end of the process.

As for the finish work, you are also right that we could use either a lightweight fairing puddy or even a micro balloon mix to fill the low spots rather than fussing with whole sheets of fiberglass mattes. However in this case we are trying to replicate the materials that are available to us in Costa Rica.

You see our area is so remote that there are no legitimate boat suppliers. The only materials we can acquire locally for repairs are standard polyester resin/hardener and matte. The best way to make sure that we can easily repair this foredeck with local materials is to only use locally-available materials from the start.

Another example of this is our choice to spray gelcoat rather than marine paint…you can’t find good marine paint anywhere in Costa Rica, but gelcoat is available in almost every hardware store. Here is a link to our last gelcoat spraying escapade: Wanderer Refit – September 2012

It seems like you guys are doing more work than you need to but I will give you tons of credit for taking on the job.

You are totally correct, and thank you for the kind support. We will keep the pictures coming and should be spraying gelcoat soon. Here you can see that Captain Jack has plowed ahead with prep-sanding the interior and the cabin. A little more clean-up and a few more repairs and we will be throwing material at her in the next few weeks.

February 15, 2013 – Day 313

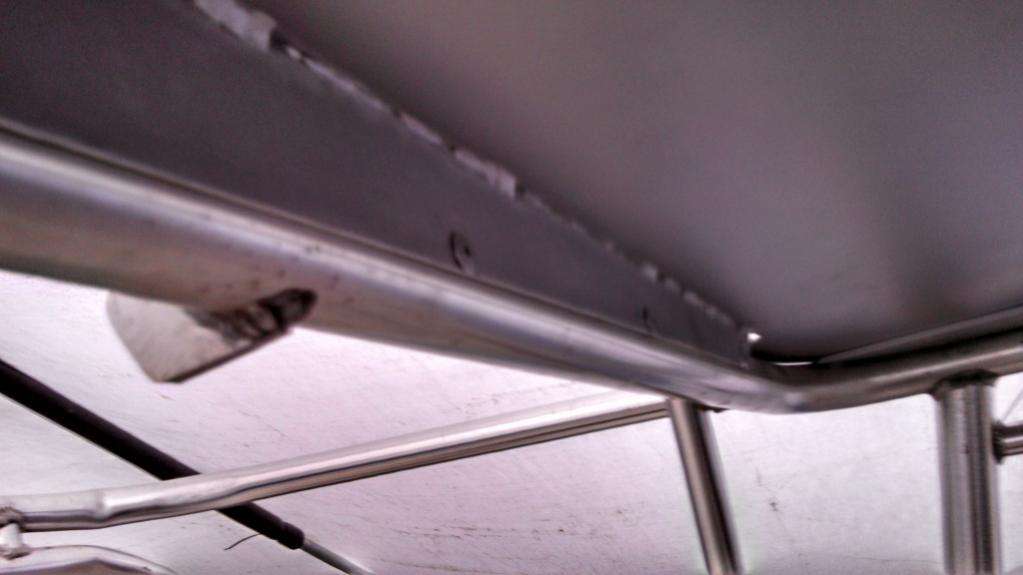

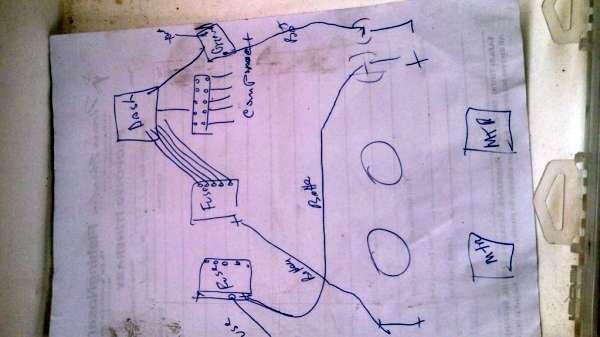

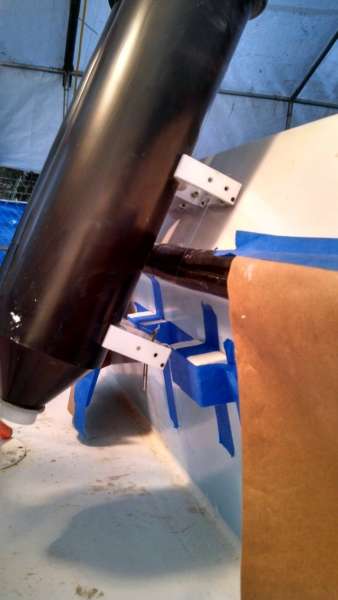

Work on The Discoverer Project has reached a fever pitch as we have multiple irons in the fire right now. First off, the tower has been delivered to our sister shop over at All Jak’d Up Motorsports where the master fabricator Craig Sutton Jr. has begun the modifications. He has already added our shade extension to the rear:

In addition to increasing the sun cover for the clients, this hoop drops the rod holders a few inches which will allow for quicker access to the rods by our Costa Rican crewman who are all under 6 feet tall. Craig Jr. will also be adding breakaway hinges to the upper superstructure so we can fold the tower down for road transit. Should be exciting and of course we will keep you up to speed as progress unfolds.

Also, Matty is running himself ragged trying to perfect the final surface fiberglass repairs to the foredeck, rubrail area and transom. The foredeck has been a long process but it is finally coming to fruition:

We were turned on to a technique that surfboard repair guys use involving wax paper on top of hot resin. The wax paper allows you to smooth out air bubbles and force resin down into small crevices and holes that can form while building up layers of fiberglass.

An added bonus is that the paper traps the heat from the catalyzer and makes the form cure much more quickly.

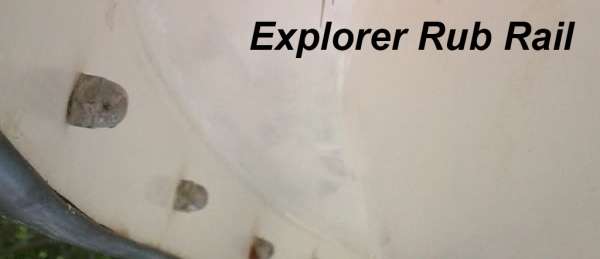

For the rub rail we elected to fill all 117 of the old holes with fiberglass plugs. The quicker and easier approach would be to run a layer of glass around the outside and be done with it, however we want as fresh a start as possible once we get to assembling the rubrail, so this tedious effort is worth it.

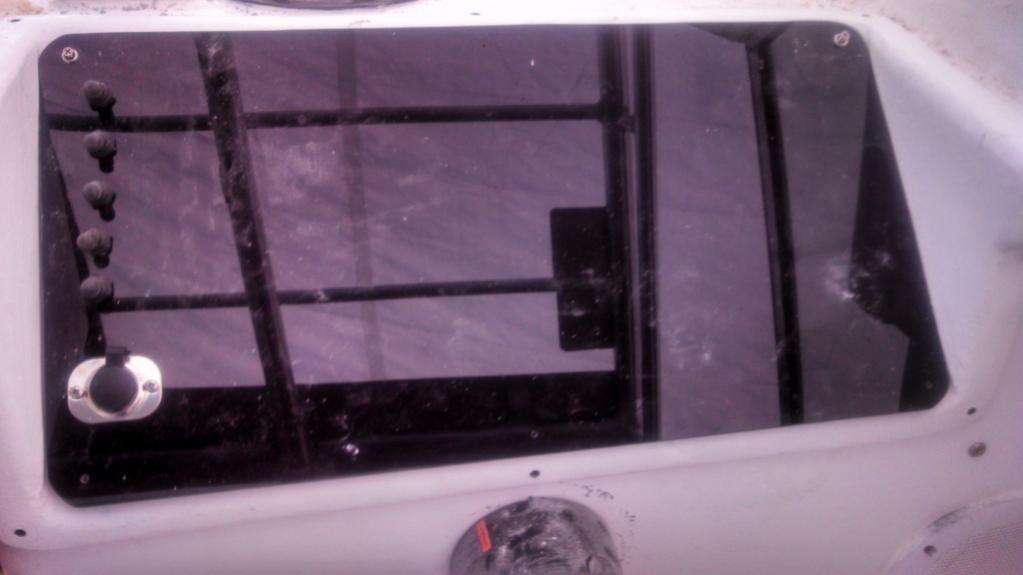

Lastly, Craig Sr. is doing everything he can to strengthen the areas around the hull where water intrusion has eaten away the wood. Of specific concern is the area around the forward deck hatch and the cabin windows.

The previous owners knew that water was leaking through the windows and rather than repair the leaks properly, then laid a bead of epoxy caulk over it and called it a day. Well that trapped moisture really did a number on the wood so Craig is taking this opportunity to fix it right. He picked and blew all of the rotten wood from between the hull elements, then methodically pushed a chopped-strand/resin mixture into the crevices. It is essential to do this in layers so as not to create trapped air pockets.

It seems like everywhere we look there are more areas that need fiberglass repair, though fortunately we are getting better and better at it each day.

We are still working hard and holding out hope that there is a pot of gold at the end of this rainbow.

February 25, 2013 – Day 323

Hi folks!

These are the kind of threads that have been going back and forth on my emails:

Matt: Sorry I didn’t get back to you on Saturday because I was busy working on the boat.

CR Office: No problem, how long for the Discover?

Matt: Fish on by December 2013 at the latest, November 1 at the earliest. Why, do you want to switch jobs?

CR Office: No thank you. See you in 2014 ha ha

So it is safe to say that we are chomping at the bit to continue progressing on The Discoverer Project but with the daily demands of jobs, wives, and serving lots of fishing clients here in the high season, it is hard to find time to invest in the boat.

Still we are plowing ahead with the small details to get this thing ready for paint. I went around the whole cabin with fiberglass plugs and epoxy filler and sealed up all the holes, big and small:

Before:

After:

This is a major undertaking that we did not expect to confront; on the Wanderer most of the holes were very well serviced (tight bolts, real stainless steel, ample 5200) we got to reuse most of the holes. On the Discoverer we have “discovered” that the previous owners were not as apt as the late Captain Jack Woodruff and instead put their faith in crappy wood screws, polychrome bolts from Home Depot, and no sealant at all.

Basically, I don’t trust a single hole on this boat so they are all getting filled and fixed.

For the top of the cabin I overdrilled all the holes to find good wood, then inserted plugs of torn-up fiberglass matte with a metal pick, forcing the material into all the null spots between the hull. I applied the hot resin with a pediatric syringe to keep the mess under control while still being able to apply the resin with some PSI behind it; between this and the wicking effect of the chopped-strand matte I am confident the these rotted out holes are now watertight plugs.

They still may look like holes, but once the gelcoat hits them no one will ever know they existed.

We also are attacking the problem from the underside with a really handle epoxy product called West 610 from West Marine / Port Supplies line of products. It’s a caulk gun-applied binary epoxy that is great for filling gaps and adhering parts; I burned through two tubes running around the underside of the cabin cap, rub rail line, and under-gunwales filling up everything that looked out of place:

These repairs may look nasty now, but once sanded down flush with the surround bulkhead (once again) no one will ever know they existed.

Also we finished wrapping the starboard side window in fiberglass tape. On the port side we tried to wrap it all with one 4-inch wide piece of tape. We learned the hard way that this stuff will bend 90 degrees, but not twice with one piece. It took a few hours with a horse syringe and a micro drill bit to fill up all the air pockets, and the raining hot resin to the forehead serves as a reminder not to try and cut corners to save material.

Here is the proper way to do it, with two overlapping pieces of tape:

In the bathroom we cut out a piece of the wall to remove the toilet, and wouldn’t you know it that we lost the piece? We made a patch out of 3 pieces of woven roven, then after an overnight cure screwed it into place over the hole and ran a coat of tape around the seams to get it trained into place.

The next day came a bead of the 610 epoxy caulk around the edges to really hold it down.

Coming up this week we will remove the screws, fill in the holes, then run a couple of fresh pieces of glass over the repair.

Before leaving for Costa Rica last week, Craig undertook the difficult process of filling the load bearing holes with pure epoxy resin. Most of the holes Matty hit will never bear more load than a compass or a radio clip, but these holes here are where the tower, rubrail, and outriggers connect; each of these objects bear extreme strain under open-sea conditions.

Craig uses the pressure of the syringe to force the epoxy resin deep into cavities all around the holes. Epoxy resin is more expensive than Polyester (which we have used heavily throughout the project) but when fully cured boasts over 2000 PSI of compressed strength (feel free to correct me forum folks, I got that number off the internet somewhere and don’t know for sure)

Lastly the cabinets on the side of the hull had to be cut in half to remove the giant fuel tanks (see prior post). It was a real PITA and to make matters worse when we reinstalled the back halves they didn’t perfectly line up flush with the front halves. Rather than go crazy trying to make these large pieces setup at a perfect level, I decided to “fake it” by applying layers of chopped strand matte in the low spots, then use wax paper (an old surfer trick) to form the curing hot resin to shape.

A little more work with the sander and these will be level seats for our clients’ behinds.

At this point in the project we are fairly experienced with this fiberglass repair process and the speed of our progress is picking up. Unfortunately March is the peak of our show appearance schedule and most of us will be out of town for 15 days out of the month. But you can be darned sure we are going to maximize every second we can to keep things moving towards a fish on for the Discoverer.

March 16, 2013 – Day 342

Hey guys. This week Matty and Craig are in Somerset, NJ promoting FishingNosara at the Saltwater Fishing Expo:

This means that Jack has the shop to himself and can get some work done without getting distracted by our shenanigans. We are so satisfied with the way the foredeck came together that we are repeating the same process on the side gunwales.

Here you can see that Jack has peeled back the top layer of fiberglass to expose the rotted wood beneath. We turned out to be pretty wise in this decision, because if you look closely several sets of rod holders have been drilled in this boat’s history.

The only way to be sure that OUR rod holder holes will be strong to replace this entire section with a fresh piece of marine plywood.

Before we left for New Jersey we took a visit from Earl Newton, the man who sold us this boat back in April. Earl is a great old boat man and is always a great source of advice for us on this project.

Earl dropped by the shop to discuss some last minute details for his trip to Costa, and we are proud to report that his fishing day on the Discoverer‘s sister ship the Wanderer brought multiple great Sailfish releases plus some nice Mahi for the dinner table.

Great work Earl…can’t wait to see you back at the shop for a good fishing story!

March 26, 2013 – Day 352

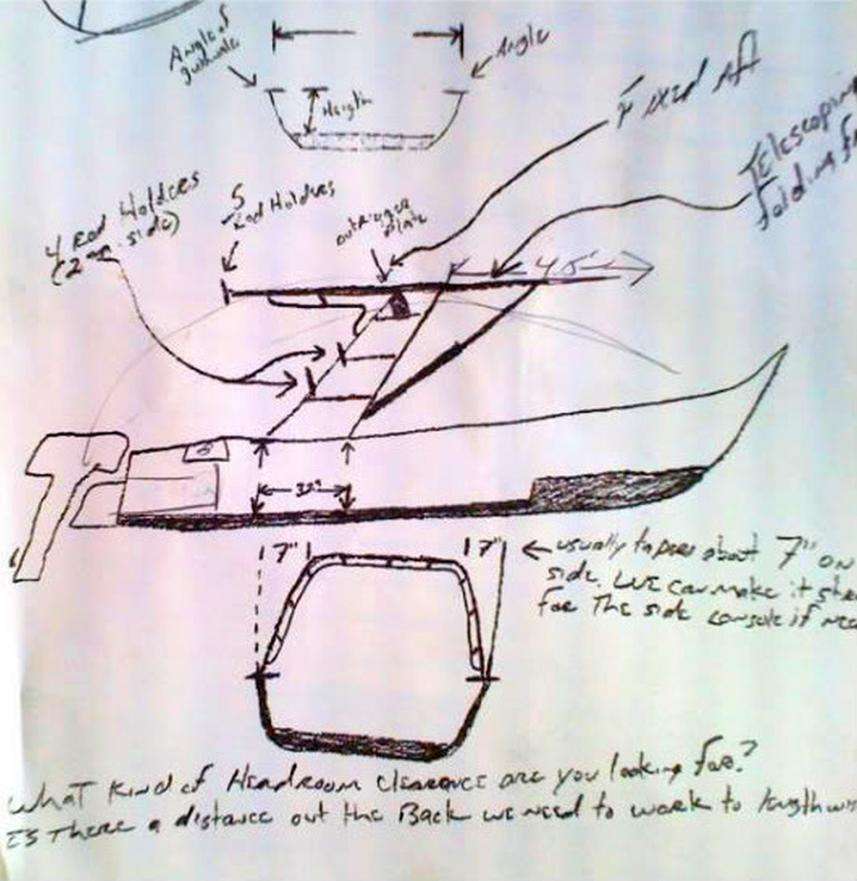

The whole team is back together in the shop and we have some great progress to report. First off Craig Jr. has finished his modifications to the tower:

The extended hoop on the rear will provide extra sun-shade to the fish-fighters in the cockpit. The real trick part of the modification is that now the tower can be removed for road transportation:

Great work by Craig Jr. and the whole crew over at All Jakd Up Motorsports!

Meanwhile we saw in the last post that Jack has completed gutting out the old rotted wood on the side gunwales, so Craig came in and fabricated epoxy plugs to fill the voids from the old rod holders.

The epoxy is really clear but the plugs look blue in the pictures because of the painters tape on the bottom.

Now we are ready to start fabricating the new wood.

We will be using the same marine-grade plywood we used for the foredeck, and as before want it to be as tight as possible to the edges so that the wood carries the stresses, not the fiberglass.

Craig is busy sanding the “floor” of this repair so that the new piece has a solid surface upon which to bond. The next step will be to encapsulate the new wood in fiberglass. Once it cures we will set it into place and start building it back up to the level of the gunwale.

This used to be difficult, but now that we’ve got the hang of the fiberglass process this one should go smoothly.

April 1, 2013 – Day 355

The fur has really started to fly in the boat shop as Craig and Matt are half-way through the replacement of the cockpit gunnels. This area had been completely eaten away by water intrusion with about three generations of rod holder holes to show for it. In the prior post we cut the new wood and prepared the ‘floor’ of the repair to accept the planks.

There is still an important step in preparing the planks: fully encapsulating them in fiberglass matte. This adds another layer of protections from future water intrusion, however if we install the rod holders correctly (with 5200 and through bolts) then this element shouldn’t ever come into play.

It’s a little tricky to made the fiberglass tape wrap around 90 degree corners so we encapsulated these pieces in two separate pours: first the top and bottom, then the sides and edges. In hindsight this was the backwards way to do it so I will use foresight and say that next time we will start with the edges.

We don’t want to leave anything to chance so we added another layer of protective fiberglass over our previous rod holder repairs. This is a little bit overkill but better safe than sorry.

We gave the planks and the floor a final pass with the sander and mixed up a batch of epoxy resin to glue the whole thing together.

This is the strongest epoxy that Fiberglass Coatings makes and takes a full 72 hours to cure. Rather than fuss with complicated jigs and clamps we opted for an old trick we’ve developed over years in the car industry.

Any ballast would do to apply this steady downward pressure, but hey we have lot of batteries around so why not?

Craig made a quick save when he noticed wet epoxy falling out of the back of the floor and thoughtfully lowered the boat trailer to level. This leveled out the pour, but there was still some voids that Craig filled by hand while the epoxy was still wet.

While we wait on this to cure we have tackled a few other projects around the boat and are feeling good that our ‘to-do’ list is shrinking by the day. Here are some of the side repairs:

Fiberglass Belly Band

Fill Voids around the tower mounts

Repair cracks in the cabin bulkheads

Finish leveling the side seats

This has been one busy week but we are stoked about the rapid progress. This week we will be finishing the gunwale repairs and tackling the last rotted element: the rear gunwale and deck.

We should be able to apply everything we have learned to-date on this, the final repair before spraying our base layer of gelcoat.

Comments are encouraged and welcomed. Stay tuned!

April 5, 2013 – Day 359

Hey guys and gals. It’s been another busy week and we are really on a roll now.

Little taste of Costa pulled up to the bar next door, and the office staff in CR got a kick out of this picture.

We were excited to remove our battery ballasts to find that our new wood has indeed adhered to the gunwale floor. The next step is to pour epoxy resin mixed with phenolic microballoons to fill up the voids between the new wood and the old hull.

This epoxy sets up slow and (with the microballoons added) has a paste-like consistency. This makes it easier to work with than straight liquid epoxy.

While waiting out the 48-72hr. cure time Craig busied himself with a few nagging repairs in the cabin and around the exterior. When working with slow-curing material it is essential to have other things to work on, otherwise one is tempted to rush into an area that is stull curing.

There are still some low spots on the inner gunwale that need to be built up so Craig got into it, while very carefully avoiding the still-curing epoxy around the wood.

This is a step when the details really count, and by paying special attention to the corners and seams we are hoping that our final layers of fiberglass mat will set up smooth and flat.

Once these low areas are built up we can form the new gunwale lip and lay up a few sheets of woven roven to finish the side gunwale repairs.

Yee haw!

April 11, 2013 – Day 365

April 25, 2013 – Day 379

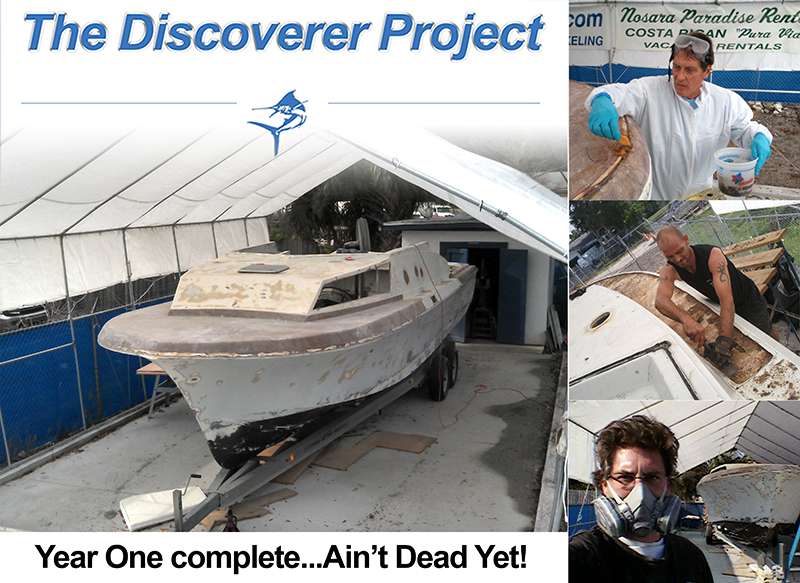

The Discover Project has increased to a fever pitch as we close in on a major milestone: completing major reconstruction of the hull. Once achieved we will spray the gelcoat and basically at that point we are back in our comfort zone. The entire project to date has been ‘off the edge of the map’ for us as we have no significant experience with fiberglass or hull repairs; once we have a strong gelcoated hull we know what to do with it.

Since the last post we ran a full mat of 90 degree bi-axial fiberglass down both gunwales. This layer encapsulated the new wood (see last post) and since we ran it all the way to the foredeck also serves to tie all our repairs together into one surface. This stuff is really cool because the ribbing makes it roll over corners smoothly. A little work with a block sander and this whole repair will be complete.

The looming storm cloud for this phase of the project has been the rear transom deck. We could tell by standing on it that the wood is softer than ice cream on a hot day, but a glance underneath revealed even more problems.

Apparently they had a pair of livewells cut into the deck at one point in time, and then someone else came in and attempted to patch them up. The result is pure waterlogged swiss-cheese; none of this area is strong enough to ‘build-up’ and incorporate into the finished product so it’s time for a fire sale (everything must go!)

The first step is to mark out the cut line. Since the existing fiberglass is so thin and weak we used a small flashlight to mark our line from below. This is a handy trick to make sure that you cut out the bad parts while leaving the good.

The next step is to score the cutline with an angle grinder or cut-off wheel. Once the outer layer of fiberglass was pierced we got our first close look at the disaster area:

Uggh. That is nasty. The third step is to cut out the ‘floor’ of this deck with a skill saw; we add a slight angle (10 degrees) to the blade to help create a beveled edge for the forthcoming deck wood.

Once the big nasty wreck came free, the final step was to clean up the cutline and edges.

After a few days of head-scratching we have devised a plan to make this rear transom deck stronger than ever. We will reinforce and strengthen the fore side of the hole and create a lip for the wood to rest upon. Then we will build wood rib supports from the fore to the aft of the hole. As long as we measure our angles correctly the new wood should curve smoothly and fit the rest of the lines on the hull.

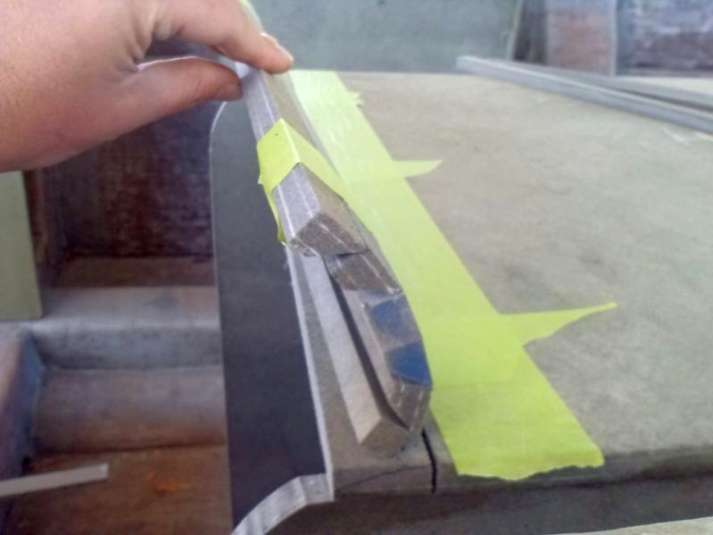

The first step is to build three sections of stiff fiberglass sheeting to build up the decayed lip on the fore side of the hole:

These were made by pressing two sheets of woven roven together between wax paper. We trimmed out the edges with a grinder and glued them into place with West Marine 610 epoxy. We couldn’t lay our hands on clamps big enough for this application, so we reverted to the ole’ tape-and-wait approach.

The overnight cure was a success, so first thing the next morning we sealed up the edges of the sheets with bi-axial so that no liquid would pour out of the sides and bottom.

Then we poured a thick mixture of epoxy and phenolic microballoons into the channel. The viscosity of this material means that gravity will pull it downward, filling all of the impossible-to-see cracks and crevices below. Once cured this should make the forward lip hard as a rock.

After a day’s curing we are ready to finalize this forward lip. I little touch-up grinding and a protective topcoat of the 610 epoxy and this are will be ready for wood. In the meantime we also got the aft lip prepared by grinding off the old material and creating a good surface to which we can bind the ribs.

In the next post we should have the ribs in place and the deckwood ready to go into place. We will have some extra hands on the project this weekend to help put the boat up on stands and finish sanding the whole thing. The much-dreamed of day when the repairs are complete and the gelcoat is flying is near…once that day gets here I hope this truck is ready to get emptied:

’til next time….

April 29, 2013 – Day 383

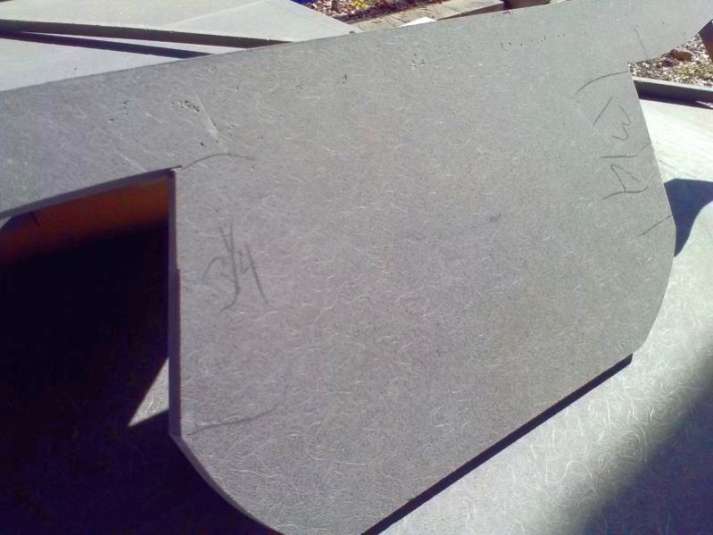

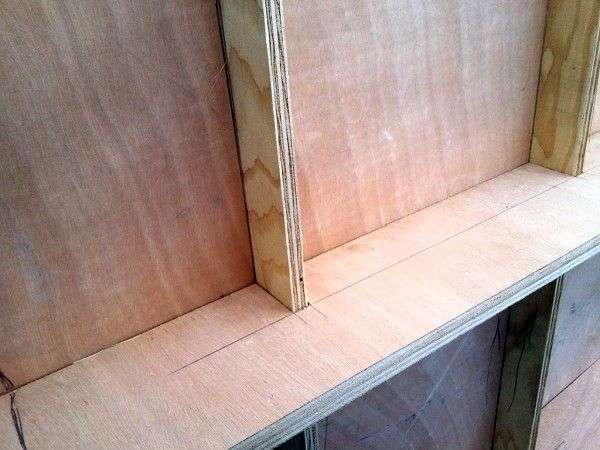

Over the weekend we finished installing the four stringers that will support the forthcoming wood for the rear transom deck. It started simply enough by gluing together two 1/4″ pieces of marine plywood together to form a 1/2 inch piece. Then we cut out four pieces about 30 inches in length; the hole itself varies from 23″ to 24″ so at this point you want a little extra wood.

Then we test fit each piece and label them according to their slot…certainly would be a fail to let these things get mismatched.

We used a plumb-line and some simple trigonometry to make sure that each stringer fits the slanted back wall of the transom. Here is an example of the fit we are going for:

Once we have a rough fit we encapsulate each stringer in fiberglass matting; an addition to strengthening the wood and making in watertight, this also add thickness that we can grind away until we have the perfect fit.

Here are all the pieces in place, supported by temporary screws:

The final step is to lay down some fiberglass to lock these stringers into place. There are some tight corners here, and one small mistake can prevent a stringer from locking in properly.

After an overnight cure, we were not pleased to find that two of the four stringers failed to adhere:

Fortunately with fiberglass, you can always grind it off and try again. Here is the final result.

This week we will be shaping and installing the top piece, then we will run our top layers of woven roven and fiberglass matting. Ideally this repair will seamlessly match the prior repairs to the side gunwales. Stay tuned!

May 9, 2013 – Day 393

Hey everybody! Craig and Matt are in Nosara this week trying to catch fish, so here are the pics from last week. To finish the major reconstruction of the rear transom deck, Craig ran fiberglass tape around all the corners underneath the deck. The idea here is to create a seal to catch the forthcoming epoxy mixture.

These are very tight corners and it is virtually impossible to create a perfect seal with no air bubbles with a single piece. That’s why Craig laid all of these corners with two layers of tape; it’s twice the work but is the only way to be sure it will work properly.

With the new plywood secured to the stringers and all the seams covered, Craig proceeds to pour epoxy mixed with phenolic microballoons into the void. This mix should penetrate all the gaps and created a bullet-proof level of strength for this whole section.

You can see in these shots that the back-fill worked to perfection with nary a drop of the red stuff falling through.

All that’s left now is to wait 24-36 hours for this epoxy to fully cure and harden, then it is on to finish fiber-glassing.

Meanwhile we are continuing to search for little spots that have evaded our repairs so far with Craig tending to the anchor box and Matty continuing to shape the rear deck, gunwales, and foredeck.

May 30, 2013 – Day 414

Hey everybody!

So we are back from Costa and fired up to keep jamming on the Discoverer so we can take it on down south for a good old time.

In the last post you can see that the new piece of marine plywood has been laid on the new stringers. After the initial epoxy set up, Craig backfilled around the entire piece with an epoxy/microballoon mixture. Notice in the final picture that all the edges were coated in fiberglass tape so that the epoxy would not seep through around the stringers.

The week before we left for Nosara it rained everyday and we couldn’t pour any fiberglass to encase the top of the marine plywood, which was still raw and exposed to the elements. The last day before leaving we got a break in the humidity and poured a hasty piece of woven roven over the wood.

You can see that there were air bubbles along the edges and that everything is far from level, but at least it is encased and can withstand the rain while we go do this:

So once we returned the next step was to level out the hasty pour from before and get a fresh start at making this thing look right. We used the 90 degree biaxial weave because the ribbing helps it hold tight to corners.

The pour came out much cleaner than the first attempt, and you can see in these shots how well the corners set up. While there are some air pockets and other imperfections that will be ground out and replaced, most of the corners achieved adhesion with no air bubbles at all.

This also allows our first unobstructed view of our marine plywood and we were happy to see no cracks, fissures, or other signs of stress in either the wood or the fiberglass.

After another round of block sanding Matt applies a hot coat of resin and wraps it in wax paper; using a spatula we can work out the air pockets and create a nearly common level in preparation for the final run with the sander.

One trick is to remove the paper as soon as the resin begins to set because if you leave it too long the paper with shred and get encased in resin, which is a pain to correct and costs time.

Next up we will apply the same technique to these fuel covering boards and the central deck cover, as well as a final pour on the nose and foredeck to bring everything to a factory-perfect level. We’ll see…

’til next time!

June 18, 2013 – Day 433

The end seems so close, but as the old saying goes: “In a 100 mile race, 90 miles is halfway.”

The true test on a project of this scope is to finish strong and not start cutting corners now due to frustration, hastiness, or laziness.

A perfect example of this challenge is the floor. Easy to take for granted and a nightmare if it goes bad, the removable fuel covers and center section are the last step to complete our new floor.

When Charlie fabricated these sections we had not yet gone ‘fiberglass crazy’ and thought that a simple brushed coat of hot resin would be enough to seal these pieces. Now the paranoia of water intrusion has grown to the point where we need to re-wrap these pieces in fiberglass matte.

In a weird way it probably for the best that we saved this center section for last; it’s 32 three-way right angles is like the final exam for fiberglass corner wrapping…if you can make these pieces stick, there is no stopping you on the fiberglass battlefield.

Meanwhile, Matt went to work finish sanding the fuel deck covers and the main center piece. This arduous process relies heavily on the plane sander (right) and the rotary DA (left); the former creates uniform flat surfaces on the top and bottom while the latter allows for the smooth rolled edges.

As tempting as it seems to start spraying gelcoat, we need to test fit our hardware so we can properly prepare their holes. First we re-installed the bow rail:

Notice that we used tapping screws here rather than bolts…we will hog out these holes, backfill them with epoxy, and then after the gelcoat will run the bolts through the epoxy plugs; this means that there is a 0% chance of water intrusion around the bolt holes.

We also test fit the side vents and the bow pulpit and anchor guide:

Lastly, we invited our old buddy Carl over to show us his tricky way to install rod holders. It’s a game of angles, with the aft-most holders pointing straight back and then rotating progressively outwards for the foreward rod holders.

(aft-most, straight back)

(forward-most, 30 degree outward angle)

Precise measuring is called for to make sure that both sides match in both their relative distance from the transom and their relational distance to the side gunwales. One inch off either way could be a major problem.

The two forward-most holes are for the fuel fillers so they are drilled straight down, however the rod holder holes have to be beveled to accept the slanted rod holder sleeve. See here how Carl makes use of some simple logic: it sticks up at the same angle it sticks down.

Notice that he is holding the tool to match the rod holder? Seems low-tech but the result is perfection:

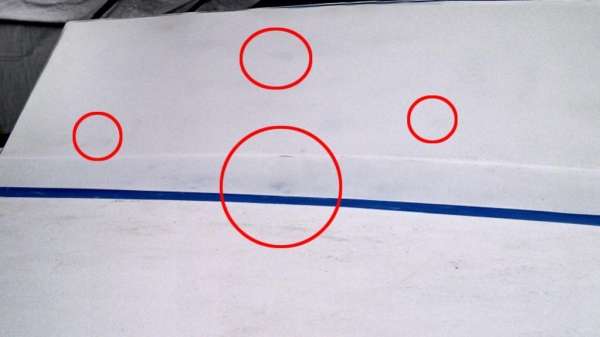

Let’s check out our new holes:

One nice by-product of this cut is that we get to see and detailed view of how our new side gunwales set up via the discharged puck:

Looks like the epoxy (red, just below the wood) and the deck wood adhered to the existing fiberglass (bottom) and our new fiberglass (top). No visible air pockets or fissures gives us nice peace of mind for us moving forwards.

The next steps include wrapping all of the new holes in fiberglass as well as the area around the console…like I said, water intrusion paranoia is at record highs!

I must say that it feels good to get out the tools and start drilling and cutting because this is the kind of boat-building we are used to (rather than all of this sanding and fiberglassing). Alas we still have to finalize our fiberglass work before spraying this thing…once that happens we will be back in our comfort zone and this boat should come together pretty quickly.

Stay tuned!

July 3, 2013 – Day 448

Things are moving fast as The Discoverer Project reached the final days of prep work and reconstruction. We are already dreaming of the day we arrive at the shop to a freshly painted hull and we can get into what we know (boat building) rather than the exploratory exercise of fiberglass repairs.

Last week we reached a major milestone when we delivered the aluminum top of the Discoverer to the folks down at Showboat Custom Coatings for a shot of their famous SB-230 coating.

It was a tough task to fit the top to the trailer and make it secure enough for a 300 mile ride to South Florida, but the end result will definitely be worth the effort. With the SB-230 applied there is no need for polishing or waxing to keep the metal shining, just a little soap and water.

Before we loaded it up Craig, Jr. gave everything one more pass with the aluminum welder to make sure that all of his seams were super-tight. Once the coating is applied all the tooling marks will be invisible; still the raw welds look great even without the finish.

As we approach the July 4 weekend, we are striving for our independence from a dastardly foe: Fiberglass. We are in the final days of wrapping ourselves up in Tyvek suits and respirator masks as we are running around the boat chasing down all the small repairs and neglected spots from the last 8 months of massive reconstruction.

Here you can see Craig tightening up the console area by injecting thickened epoxy for strength, then applying a protecting layer of fiberglass matte around the seams.

Later Craig went to work on the seams around the fuel covers in the deck, first hand-sanding the divide and injecting epoxy then running a piece of fiberglass tape to keep the repair watertight.

Matt set about leveling the rear deck. This is a little tricky because the all of the different levels in play here. In order for the level sander to do it’s job everything has to be above grade before the sanding process begins.

On this center section we had to cover up all the divots where Charlie screwed in the piece. You can see in the above picture that each cavity was filled with a 1 inch square of chopped strand, then we started adding uniform layers over that relatively level repair.

In the last post we began test fitting all the hardware to make sure that all of our fiberglass work hadn’t disrupted the fit of the pieces. This is also the time to beef up the structures and watertightness of these areas.

The block of wood under the gunwale is designed to add another layer of firmness to the cleats on the rear of the boat, since this is where our crews tie up the panga boats and (in an emergency) tow other boats. It is crucial that this cleat be a rock, so this wood block is 100% marine grade plywood wrapped in two layers of fiberglass. No chance of weakness due to rot on this piece.

Water-intrusion leads to wood rot, and wood rot leads to problems. To combat this issue we plan on using a custom boat trick on the Discoverer called epoxy-sleeved bolts. The concept is simple but the execution is very precise.

On the left is the way most boats are put together. The wood is encased in fiberglass, resin, or epoxy (represented as pink) to keep the water out; however over time the seal around the bolt head, nut, and shaft of the hardware can allow water to seep in. With epoxy sleeving (right) each hole is overdrilled then backfilled with epoxy. Once cured, the epoxy plug is drilled to the proper size leaving behind a “sleeve” for the bolt to pass through.

Here we see the foredeck with all the hardware removed, the holes overdrilled, and the epoxy setting up in place:

We did the same thing on the rear cleats…this is why we put the wood block in place first, so that the epoxy sleeve will stay constant all the way down to the nut.

We also cap the epoxy plugs top and bottom with a layer of fiberglass to keep the whole thing snugly in place and at level with the surround decks.

We also wrapped the deck pipe hole with fiberglass tape to seal it from the elements, finalizing a front deck that is now truly bullet-proof.

The last step is to drill our pilot holes so we don’t lose these plugs once the gelcoat goes on. We feel confident that this approach will keep the internal guts of the Discoverer dry in the immediate future and well into the next few years as this hardware will be removed and re-installed regularly over time.

The last few steps are underway now: finishing the level sanding of the decks, strengthening the fighting chair mount, injecting foam around the gas tanks, and about a half dozen other little items. By this time next week we should be shooting gelcoat.

Almost home!

July 26, 2013 – Day 471

It’s hard to believe that three weeks have passed since the last post, but know that we have been neck-deep in The Discoverer Project for every second of it and we have some excellent results to report.

In the last post we completed our epoxy sleeves for any bolts through the decks.

We turned our attention to final details and we doggedly approach painting time; first up was filling small fiberglass pit-pockets with a muddy mix of polyester resin and phenolic microballoons:

This stuff finished off so smooth after sanding that we decided to coat the entire deck and floor with the same process:

It’s always the out-of-the-way spots on boats that are the tricky ones, and Craig set about chasing down potential water intrusion spots in every conceivable place.

During this work it was discovered that the sides of the boat in the rear had too much flex in them for our liking, so we added a horizontal fiberglass stabilizer from the lip of the fuel deck to the outer hull.

We patched in a small overlap section in the back so that this repair would be continuous down the whole side of the boat.

We then backfilled the newly airtight cavity with Great Stuff Pond and Stone which is much more water-resilient than open-cell Great Stuff.

Matt enclosed some raw wood under the console which was so out-of-the-way that an access panel needed to be cut in the bathroom floor:

Craig continued to chase last minute items:

The nose:

The mid-ship access covers (freshly cut and wrapped in fiberglass):

The feet around the fighting chair mount:

Fuel tank rear supports:

Final clean-up and wipedown:

Lastly, we are lifting the level of the footpads about 1/8 of an inch where they bolt to the deck.

Plus it adds that much more strength and resistances to water intrusion in this critical area.

So where was Matt during all this?

Let’s get painting!

July 27, 2013 – Day 472

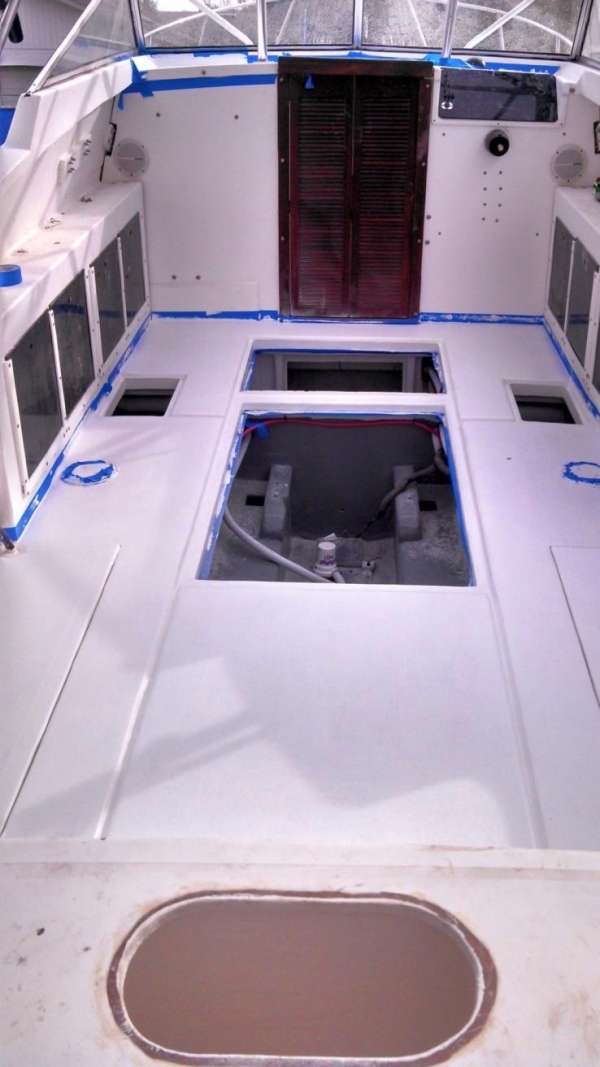

It took a whirlwind day of painting, but we sprayed every drop of gelcoat we had and have a pretty good jump on the paint work for The Discoverer Project.

Our pal Ginno was the trigger-man with Matt backing him up on the mixing station.

Let it fly!

We’re pretty pumped that our gelcoat spraying technique worked out and we got two coats on before running out of materials. We are certainly excited for the next 15 gallons to arrive on Thursday so we can finish this thing off!

August 3, 2013 – Day 480

Ah the misery of logistics! Just when we were getting a head of steam built painting the white part of the boat, The Discoverer Project hit a snag when we ran out of gelcoat, hardener, and paint strainers.

We waited 6 days for our Thursday delivery from FGCI and there is only so much piddling around one can do on a boat that is all ready for paint.

Then on the fateful day to spray, Ginno the painter called off because he had some other projects to do. We decided to proceed with the final paint work ourselves rather than putting the project off any further.

We started by hand brushing gelcoat over any spots in the hull that needed extra material, and as it set-up we sprayed more gelcoat over the top.

Also, Matt came back around and filled in the couple of square feet where the lack of white gelcoat had hampered our first spray. Check out the rear transom deck, finally completed:

All told we are pumped to have reached this point, but the next challenge is equally murky and daunting: how to best prepare this gelcoat-only paint job to make it look shiny and new.

We are planning on wetsanding the whole thing with P400, P600, P800, and P1000 over the next few weeks. Until then we are proud of this result:

August 8, 2013 – Day 485

Still rocking and rolling on the paint work for The Discoverer Project. First up we slid the tripod boat stands a few feet so that we could spray in those areas:

Also we discovered that one of the tripods was hiding a dirty little secret: two cavities in the hull that went all the way to the original fiberglass. Here is the repair process:

Most recently we rolled, brushed, and sprayed some nice marine grey gelcoat into all the sub-deck areas.

Also we have gone around the new paint job filling in tiny little air pockets…these look rough now but will sand down beautifully.

Feeling good and looking good. Stay tuned!

August 19, 2013 – Day 496

Hey everybody!

When we left off we were looking at a fully-sprayed but still-unfinished wad of fiberglass and gelcoat; the challenge now is to get this thing looking like a proper boat!

First order of business was to lay down some texture on the floor of the boat. On factory boats the texture is usually built into the mold so the lines are geometrically perfect; since this is a rebuild we have to rely on two-inch masking tape and steady hands to get those perfect lines.

First we sanded down the original surface with 180 grit (wet), then taped it up. After a blow-off and an acetone wipe the new gelcoat would adhere both chemically and mechanically. We brushed on activated gelcoat and quickly rolled the texture with a GlassKoter roller cover; they claim that these leave less lint behind than a standard roller, but the pictures attest that it still left some.

The second coat was required to achieve the proper 30 mil depth that we were after. We’ve been told that as long as you apply your second coat within 12 hours then their is no need to sand or acetone between coats.

We are confident in this approach after completing the floor, so we replicated the procedure with the fuel covering decks before moving on to the foredeck.

The foredeck was a little tricky because of the long continuous front sweep and the long reach required to get to the center; when working with activated gelcoat you have to move fast, so a little foresight goes a long way. We had four ladders set up and a long-handled roller to maximize coverage to the middle of the deck.

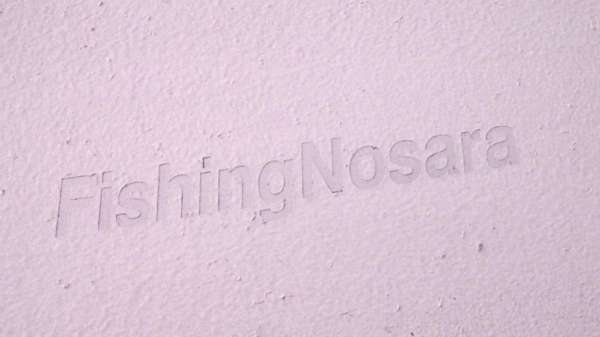

Matty was feeling pretty confident with this texture coating by now, so he tried a little experiment on the foredeck. See that little FishingNosara vinyl sticker in the middle?

Check out the result when removed after the second texture coat:

Meanwhile, Craig and Jamaal have been fixated on the exterior appearance of the Discoverer. Craig picked out a nice pair of teak planks for the side gunwales and is scouring the southeast for two matching-grain planks for the transom.

We are aiming to match the look and functionality of the teak covering board on our current T-Craft, the Wanderer.

Also, Craig made the trip down to Showboat Custom Coatings in Pompano Beach to pick up our refitted tower. They hit it with their special SB230 coating which should make this aluminum bulletproof forever. We’ll have a full report on their process and images from their shops soon!

Lastly, our buddy Jamaal has brought his deep experience with finish sanding to bear on the outer hull.

He is wetsanding the entire hull using a 6 inch DA and progressively increasing his grits from P180 up to P1000. Here is where we are now, just after the P600 and before the P800

You can see that it is starting to shine in places, and more importantly there are no spots where the fiberglass is showing through; this means that we have achieved proper depth with the blue gelcoat.