The beginning of the rainy season in Costa Rica is September 1st. While most resorts furlough their employees, at Nosara Paradise Rentals and FishingNosara we keep our full staff together for two months of intensive maintenance and expansion of our boats, vehicles, safari carts, and properties.

In this special edition of the Costa Rica Fishing Report, we will take a behind-the-scenes look at the projects and people that will make 2012 our best year to date.

The Wanderer will be entering her third year of service (man, time flies! It seems like yesterday we sent the Wanderer to Nosara) and she was ready for a major refit. An every-day boat like this demands lots of annual upkeep, and this season put a few new scars in the blue beauty that would take Craig Sutton Jr.’s expertise to repair.

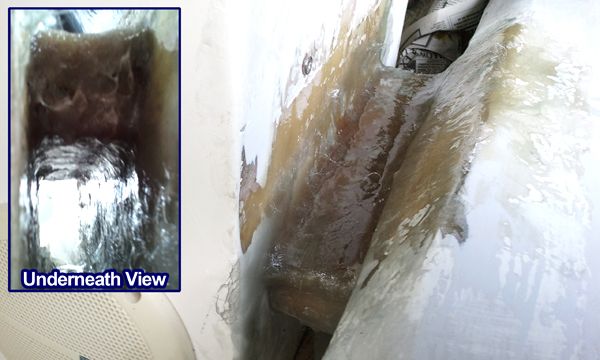

In late August, the Wanderer was damaged when she was engulfed by a rouge wave at her mooring point in Garza Bay. As the 31-foot craft bucked in the waves, the entire weight of the boat clung to the rope through the steel pulpit on the nose.

Here is what Craig was looking at upon his arrival on September 1:

The first step was to prepare the work area with a makeshift tent to keep the exposed fiberglass dry; this ensures that the new fiberglass resin will set up and harden without trapping any air bubbles or wood-rotting moisture.

Once Captain William and First Mate Alex completed the rain guard, Craig and Matty got down to the dirty work of sanding/grinding the damaged material.

Now it’s time for some fiberglass. Because of the huge industries of boating and surfing, the quality of fiberglass resin and hardener in Costa Rica is actually better than what we get in the USA; it has less impurities, sets up faster and sands cleaner.

Notice how Craig puts a wad of material as deep in the hole as possible; this works in conjunction with the layers inside the anchor box to create a pure fiberglass plug that is form-fit to the hole.

After the first day of fiberglass, the nose of the Wanderer was watertight once again.

However a few more coats of resin and a lot of fine sanding would still be required to bring this area back to pre-damage conditions.

Notice how the deck line is still not quite straight (see right); we let the repair cure and dry before coming back a few days later to sand, add more fiberglass, and put the finishing layer on.

Craig and Matty were back at it on September 7 for the final touches. By using a flat edge of cardboard rather than a paintbrush, Craig was able to create a near-perfect flat surface for the final layer.

One more late night of sanding, and Craig stepped away from this repair confident that the nose of the Wanderer is stronger than before and the surface under the pulpit is as smooth and level as a dance floor.

Of course it is easier to have a professional do your fiberglass work (or any boat work for that matter), but the quality and attention to detail that comes from working on your own boat can not be understated.

Take for example the passageway to the forward observation deck. The Wanderer‘s clients have grown to love this panoramic view of the Pacific for photography and the easy access to sunbathing on the prow.

These photos (right, below) were taken in November 2009 when this boat was fresh as a daisy.

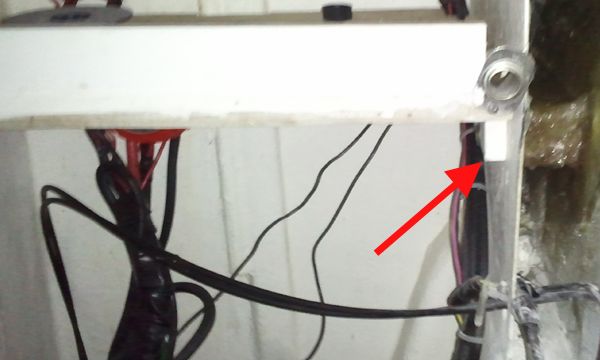

Unfortunately this porthole has taken a beating over the last two years and the bolt hinge got completely stripped.

While waiting on fiberglass to dry, Craig tracked down a tap-and-die set and cut a fresh hole for the hinge bolt. This repair, while small in scale and expense, is an example of the attention to detail required to keep a 31-foot boat running in Costa Rica.

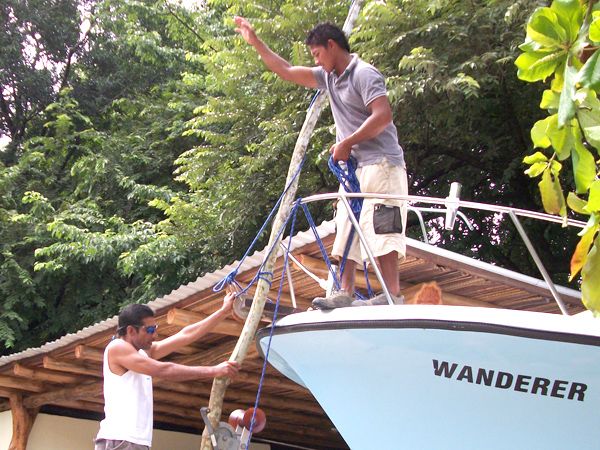

The final step to get the Wanderer ready for many more years of bad to the bone billfishing was to tighten the canopy top and freshen the 5200 Marine silicon that keeps the sea spray out of the cabin.

After lifting the roof and supporting it was some trees we found laying around (“Costa Rican jackstands” Matty called them), we applied fresh 5200 and 3.5 inch new stainless screws to replace the 20+ year old, 2.5 inch fasteners.

The increase in strength all-around is obvious, ensuring many more years of service from the rugged Wanderer. Craig and Matty left Nosara on September 10, then Captain William and Alex finished the paint work on the nose,

First Mate Alex is also a first class carpenter as evidenced by this beautiful new rigging table in the cabin of the Wanderer. This replaces a worn piece of paneling that did nothing to add to the look or function of the cabin. Now we have this great multi-use space for years to come.

From the nose to the propellers and the bottom paint to the roof, the big blue beauty will be all fixed up and ready for action come November 1.

Meanwhile Captain David was busy prepping the Explorer to get back on the water ASAP. The next few months will be a ‘soft’ off-season, meaning that if there is a break in the rainy weather then the Explorer will be ready to go fishing.

Captain David was hard at work redoing the bottom paint and some light maintenance to the cockpit, while Craig and Matty went about strengthening the hull supports of the Super Panga.

When we first launched the Explorer in December 2010 it was obvious that the added weight of the aluminum superstructure would eventually wear out the hull. To remedy this Captain David installed wood blocks between the gunwales and the consoles to share the load throughout the hull.

With 9 months of fishing under her belt, the Explorer shows no signs of wearing out; therefore it is time to make this quick fix into a permanent solution. Once again Craig’s skills with fiberglass were put to the test. After scraping and grinding off the old fiberglass patch that had been holding the wood (above), Craig encapsulated the entire wood block in fiberglass while permanently securing it to the consoles with 3.5 inch screws.

The result is stunning! Once sanded, primed and painted these supports will look like they were part of the Explorer from the beginning. Excellent work by Craig, especially getting to the cramped underneath areas with hot fiberglass resin.

While Craig was up to his elbows in fiberglass, Matty went around the boat ‘freshening’ the hardware. Saltwater has a nasty habit of eating away at metals, and anything less than 100% stainless steel will not last very long in Costa Rica. It turns out that the hull manufacturer made a mistake when they installed the cleats and used less-than-stellar metal for the hardware. See the rust stains:

These will only get worse, and left unchecked will leave nasty brown streaks on the hull. Fortunately, this situation is easy to address with simple hand tools, a green scouring pad and a few dabs of that magical 5200 marine sealant.

In order to create an even bead of 5200 it is best to apply a small dab to the threads and turn the screw as it is inserted. This makes an even seal that keeps the saltwater out for years to come. For the final look some people like to leave the rounded bead of 5200, though Matty picked up a neat trick from a local Tico for creating perfect seals without making a giant sticky mess.

“Back in December I was 5200-ing the footplates for the superstructure and making an awful mess,” Matty recalls. “This 10 year old Tico kid was watching and came up to me with a bucket of soapy water and begin pointing at the 5200 mess.” “After some futile Spanglish and confused looks the kid put a bit of soap on his finger, swiped it down the bead of 5200 (leaving a perfect seal) and showed me his finger…which didn’t have a single molecule of sealant on it!” “Since then I never run 5200 without some soapy water nearby.” Check out the improvement from the unfinished bead (above) and the finished seal (below)

Craig and Matty also did some finish work on the Explorer. Captain David installed a new cutting board on the rear of the boat, and some work with a finish sander got her looking like a factory option rather than a DIY project (Special thanks to Dan Rey for letting us borrow the sander).

Lastly, we did a little cabinet work on the consoles to reinforce the factory shelves under the consoles. The little fiberglass nubs that held the shelf up were not destined to last very long, so Craig built a dead leg under the shelf and tied it into the newly fiberglass support block.

The result is a shelf that can stand up to the rigors of daily big-time sport fishing. On September 16 we received this email from Manuel: “The super panga is ready for the action again on Monday.”

Here looking forward to another great season on the barroom brawler called the Explorer! |

The Guiones Beach Safari Carts have become a staple of the Nosara community in just 8 months on the road…you can’t go anywhere in town without seeing one of our carts. With demand skyrocketing for carts in 2012, we enlisted FishingNosara Technical Director Jack Weinmann to set up seven more carts for the rough roads of Costa Rica.

This batch includes four standard carts complete with turn signals, seat belts, headlights and more. Also included are a pair of 6-passenger shuttles and a customized pink cart; a portion of the proceeds from this cart goes to benefit breast cancer research.

We also enlisted the newest member of the team for this project, Mr. Mitchell McQuien of Arlington Auto Sales. With Captain Jack handling the modifications and Mitchell taking care of the details, these carts came together quickly and smoothly. By early August, they were packaged up and ready for shipping.

Regular reader of this report may recall that in January we tried to load these carts into the container with a pickup truck and some ATV ramps in the middle of a driving rainstorm.

This time we chose to use Dewey’s Towing and load them on a sunny day. Not surprisingly we got it done in a fraction of the time and without nearly killing ourselves.

On September 14 the container was safely delivered to our office in Guiones Beach without incident, and the boys have them ready for action.

I appears that Arturo is already imagining how sweet he’ll look in this 6-passenger shuttle. Look for these hot wheels to be kicking up dust this season and beyond! |

One thing should be clear to all of our readers, guests, and friends: All the boats and houses in the world are useless without an excellent staff working to keep it all up.

Thousands of you have lounged around our pool, and strolled through our gardens and generally soaked up the ‘Pura Vida’ spirit at Nosara Paradise Rentals; however almost nobody knows the massive amount of work required to keep our little slice of paradise in good working order.

Here is our head groundskeeper Grevan finishing the new gardens for Los Quartos. This is the man behind our world-renown privacy gardens and nature preserve. Grevan’s expertise and dedication are of paramount importance to the continued success of Nosara Paradise Rentals.

The extreme conditions of the rainforest are murder to the house paint. We are incredibly lucky that the boat crews are great painters and most importantly work well together. David, William, and Alex show great pride in their work on and off the water.

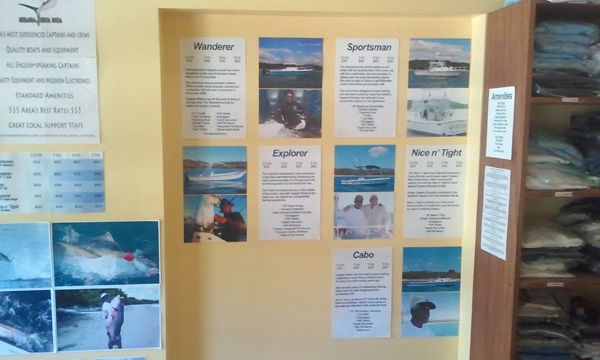

There is plenty of work to do in the office as well with Arturo and Manuel busy painting and laying out the new fishing wall to Matty and Javier working to perfect our new state-of-the-art computer system.

There is plenty of work to do in the office as well with Arturo and Manuel busy painting and laying out the new fishing wall to Matty and Javier working to perfect our new state-of-the-art computer system.

With all of this activity in the office it was hard to believe that this is technically the ‘off-season’. In fact, Nosara Paradise Rentals has remained open in the rainy season while other resorts are shuttered and many guests have enjoyed their stay.

Scooter and Christa Newell from Florida had a relaxing surf vacation, and Robyn Nutt and her family enjoyed our beautiful garden campus.

Of course we have learned to expect the unexpected; on September 4 a powerful lightning storm hit our campus and blew a wireless router clean off the wall of Casa Tranquilo. It also took a fist sized chuck out of our poolside pumphouse.

Still we like to keep the atmosphere light and fun during these long months of maintenance. Check out ‘el jefe’ Javier Hernandez showing how to get the ripest papaya from the tree behind the office:

And check out First Mate Alex showing off some mechanical skills in restoring a rusty old beach cruiser up to near-perfect condition.

Even Concierge #1 Manuel is using his time this off-season wisely; he is going back to school to pursue a degree in financial accounting. So far so good!

Things are really looking good for the 2012 season and we can’t wait for visitors to start showing up in droves come November.

However for those of you who want to see a different side of Nosara, think about coming down in September and October for peaceful, uncluttered access to this rainforest paradise. The ‘off-season’ in Nosara is a perfect time for people who want to lay back and recharge themselves for their own upcoming seasons.