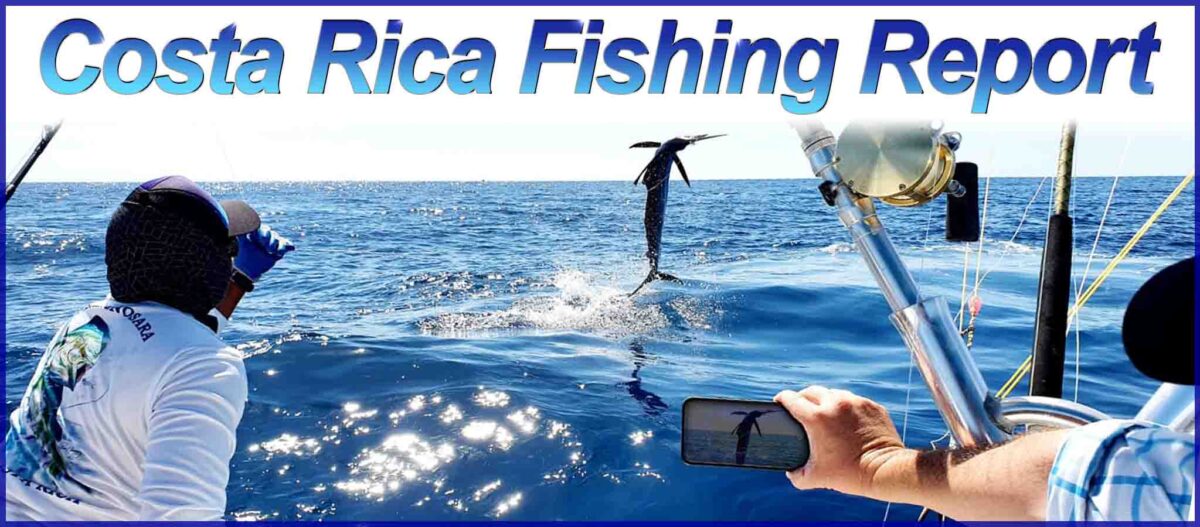

Earth-Shattering moment on the Wanderer today as the Good Doctors pulled off a simultaneous Double Marlin Release! We have pulled off several Double Sailfish releases in the past and a few memorable Marlin/Sailfish doubles, but this marked the first true Double Marlin release of the season so far.

To describe the moment of the strike as ‘chaotic’ is an understatement; the skill of Captain William to keep these high-flying monsters from getting tangled only trumps First Mate Alex’ fish-handling skills.

Wrangling 1000+lbs. of angry billfish at once is no small feat, but we have always said that the Wanderer is known for defying expectations.

Amazing work by the flagship!