It’s the rainy season in Nosara and we all know what that means….boat maintenance time! The captains and crew have the grounds of Nosara Paradise Rentals all to themselves and are dead-set on reloading the fleet for another record setting season. Let’s take a lot around the grounds:

The Explorer looks good as usual, and it’s required repairs are relatively minor and cosmetic.

The Adventurer is so new that it only requires some screw tightening. That only leaves…

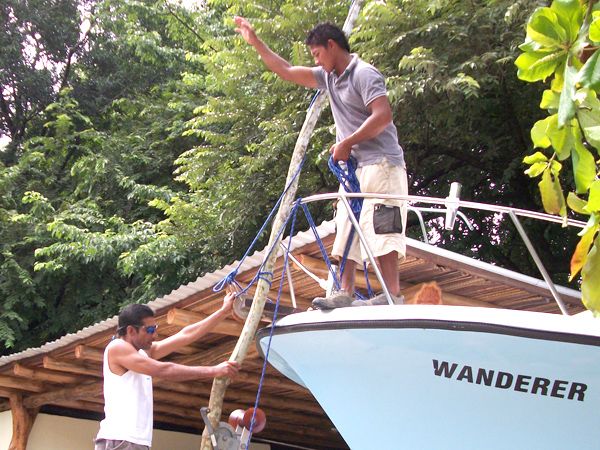

The mighty Wanderer! After 3 years and nearly 600 trips our flagship is quite ready for a complete repaint and refit. This craft has taken everything that the Costa Rican environment could throw at her and is still hanging tough, but if you want a boat the last for 30 years you can’t skimp on the upkeep.

Our typical offseason painting on the boats consists of spot fixes and lots of masking tape. It is our goal to bring this paint job back up to the original level that we shipped to Nosara, so we are disassembling as much as possible. No tape lines on this boat!

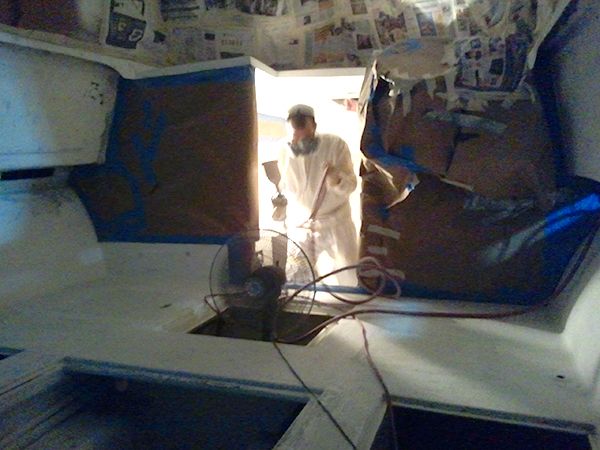

Back in 2009 we were satisfied with the condition of the cabin, but now it is time for the chambers to get some TLC. The wood is still good in the cabin, but the paint is beginning to fade. Also we are deleting the hardwood shelves that ran along the sides of the cabin in order to save weight and reduce clutter.

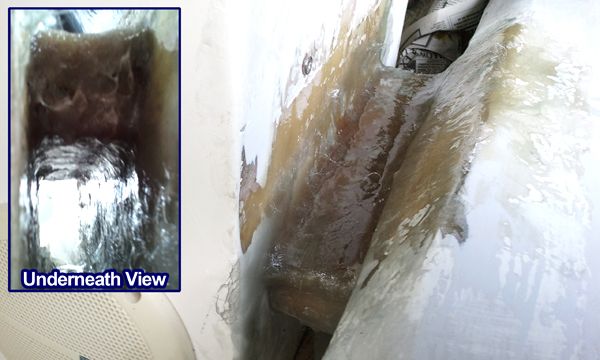

The fuel tanks were another issue of concern. Three years ago we installed the tanks in what we thought was a watertight compartment. We were so confident that we did not paint the tanks so they are vulnerable to even the smallest drop of moisture that could sneak through.

}

}

Looks like we dodged a bullet there! This tank is almost exactly as we shipped her and we will not make the same mistake twice. A protective paint job and fresh foam will help us sleep a little easier at night.

Craig, Craig Jr., and Matty showed up on September 5 (one day after the big earthquake) and brought the requisite sanders, sandpaper and paint supplies. Removing the bottom paint is the hardest job we have ever asked of the boat crews, and despite the pain and itchiness they have made excellent progress stripping off 20+ years of old paint.

Despite the backbreaking discomfort of paint grinding, the crew jammed it out and kept their usual high spirits through the difficult times. One small step for man, huh David and Alex?

The prep work continues inside where the boys have dutifully taped off the cabin wood and started double-action sanding the floor, walls and ceilings.

First Mate Alex is an ace carpenter, so he is in charge of sanding and refinishing all of the cabin interior wood, the cabinetry, and the dis-assembly and cleaning of the fighting chair. Take a look at the shine on this wood:

With the fighting chair we have sanded all off the old gelcoat and have decided to let the beautiful wood grains shine thorough. Alex got his hands on a thick chunk of pichote wood and formed this exact replica.

With the fighting chair we have sanded all off the old gelcoat and have decided to let the beautiful wood grains shine thorough. Alex got his hands on a thick chunk of pichote wood and formed this exact replica.

Once everything is stained and put back together this should be a beautiful piece of functional fish-fighting art.

After a few days of sanding the bottom paint off, we realized that the boat’s trailer was obstructing our ability to reach all of the area. Furthermore the impeded access would create too many null spots where we would have to come back and paint later.

The solution is pure Tico engineering…using two bottle jacks and big sturdy tree limbs as lifts, these fellas propped up this 3000+ lbs boat and slid the trailer out from underneath.

Sure enough this change enabled Craig jr. and the crew to finish sanding the bottom of the Wanderer. In hindsight this is the first step we would have taken, and in the future we will do all boat work down here in a saddle similar to this one.

We also employed a little local knowledge in dealing with another persistent adversary: the rain! During the rainy season in Costa Rica you can count on at least one gutter washer per day, usually in the late afternoon.

Our crew rigged up a tarp roof out of four smaller tarps and it is suited to repel most of the direct rainfall. Still with the humidity hovering around 99% we have to deal with condensation forming on surfaces we are trying to prep.

Matty and Carlos spent the better part of two days getting all of this paper and tape to adhere to the hull. Most of the effort was in pre-wiping the surface with acetone and quickly applying the tape before the water could re-establish it’s hold.

Also we ran a little short of paper so we resorted to the local tabloids…not only does this boat now repel paint but is also helps keep us up to date on soccer scores and silver screen starlets.

There was prep work still underway in the cabin and cockpit when Craig Jr laid down the first coat of gelcoat on the bottom. In their fervor to scrap the old bottom paint off, the crew accidentally went too deep in spots and exposed the top layer of fiberglass.

Here is the final prepped surface before painting; notice that the rough spots have all be filled with fiberglass resin and sanded down flush. Hopefully these patches will blend seamlessly once sprayed.

We thinned the gelcoat by almost 50% in order to spray it (most painters apply gelcoat via brush) and Craig drew the unenviable task of applying this nasty stuff. The mix of acetone thinner and resin catalyzer was a potent brew that required full facemask respirators to work around.

Due to rain it took a whole day to apply the bottom coat and another long night of spraying to finish the transom and all of the deck pieces.

We were blown away by the great results from this chemistry experiment. Check out the smooth coverage of our two gallons of sprayed gelcoat:

It was around this time that disaster struck: our Dupont Imron paint had been seized by the Costa Rican port authorities. Apparently our shipping agent forgot to declare the paint products and our precious supplies disappeared into the underworld.

We first learned of this issue on September 6 and after two weeks of fruitless phone calls, the boat was nearly prepped and the whole project would come to a screeching halt without paint.

The boat crews stayed on task like true soldiers and finished up the surrounding work while the gringos set about figuring out how to paint this boat.

FishingNosara is famous for taking a bad situation and turning it into a legendary result, and the repaint of the Wanderer had become a bad situation. Finally the solution hit Craig Sutton like a bolt of lightning to the forehead: “Let’s gelcoat the whole dadgum thing.”

After all, every Tico panga boat you see gets an annual coat of gelcoat slathered on via brush and you can buy the stuff at any hardware store. The DuPont paint is world-class, and as such it is hard to find in such a remote location.

If we could combine the Tico’s time-proven approach of gelcoating with the gringo spray technique and attention to detail, then we might have a real one-of-kind result that will look great and last a long time.

Craig called on the experts: he asked Charlie Keen of the Discoverer Project and our good buddy Chappy if gelcoat would adhere well to fiberglass. Their replies were identical: “Well that is what it’s made for, Craig.”

Convinced, we dispatched Cumi to the Sur paint store in Nicoya and he retuned with 8 gallons of white gelcoat, 2 gallons of black bottom paint, 16 cans of acetone thinner, 10 more rolls of masking tape, and a few ounces of blue pigment.

On September 16, Craig Jr. and Matty set about turning this nightmare into a dreamboat. They hustled through the last few repairs on the boat, most significantly patching the old rubrail bolts and touching up last September’s front pulpit repair.

By 5pm all the fiberglass had cured and Carlos finished the final acetone wipedown. Normally the rains blow through at this time of night but it was an eerily clear evening; also Matty and Craig Sr. were scheduled to fly back to Florida to next morning.

The die was cast: all-night paint session!

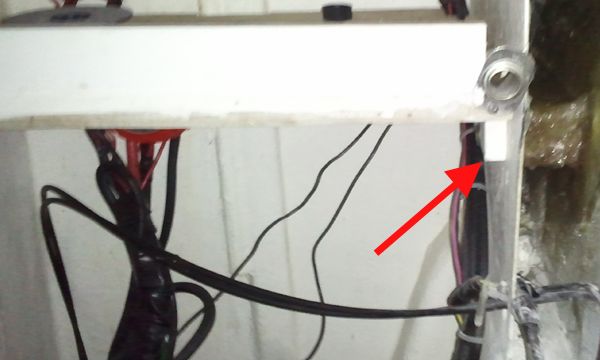

Craig Jr. started with the hardest part which was the front cabin. This entire area was masked off tighter than the lid on a Pringles can, and literally every second of spray exposed Craig’s skin to low-grade chemical burns. Oxygen was scarce and only a small household fan was available to provide circulation.

This is what hell on Earth looks like:

After that horrible experience, the remainder of the interior was a breeze.

The floor was a little tricky, but the momentum was building and there was no stopping us now. Craig Sr. came through with dinner around midnight and the boys continued hammering away with only a few Flor de Cana breaks.

By 4am Craig Jr. was working down the sides…the home stretch!

They finished the job at 5:30am just in time for Matty to load up and head off to the airport. With his last gasp of energy, Craig Jr. issued the following orders to the crew: Don’t touch the paint, and take the sanding operation to the other side of the property.

After 12 well-deserved hours of sleep (and cure time for the white top), Craig Jr. kept the ball rolling by spraying the bottom paint:

Then came back on Saturday to apply the final coat of blue-tinted gelcoat.

After two weeks of worrying and stressing (not to mention almost working the crew to death), the Wanderer shines like a new dime.

Captain William is pumped with the finish, and Craig Jr. looks relieved to be on the way back home. The boys will finish up with the cleaning and will begin pre-assembling the components over the next four weeks.

Craig Sr. and Captain Jack will be back in late-October for the final tightening and water testing. After this process the FishingNosara flagship will be lighter, cleaner and shinier than ever.

There is plenty of work to do in the office as well with Arturo and Manuel busy painting and laying out the new fishing wall to Matty and Javier working to perfect our new state-of-the-art computer system.

There is plenty of work to do in the office as well with Arturo and Manuel busy painting and laying out the new fishing wall to Matty and Javier working to perfect our new state-of-the-art computer system.